- Study on the Strain Sensor by Using Iron(III) Sulfonate Complex/Thermoplastic Polyurethane Composite

Division of Advanced Materials Engineering, Kongju National University, 1223-24 Cheonandaero, Cheonan, Chungnam 31080, Korea

- 철(III) 술포네이트 착화합물/열가소성 폴리우레탄 복합체의 스트레인 센서 응용 연구

공주대학교 공과대학 신소재공학부

Reproduction, stored in a retrieval system, or transmitted in any form of any part of this publication is permitted only by written permission from the Polymer Society of Korea.

In this study, the strain sensor application based on thermoplastic polyurethane (TPU) and iron(III) p-toluenesulfonate (FTS) is investigated. In general, FTS has been utilized as an oxidant for the oxidative-coupling reaction of conductive monomers for the synthesis of conducting polymer. In this study, FTS is considered as an active component for strain sensor that exhibits changes in electrical resistance due to strain for the first time. The TPU-FTS composite based strain sensor can detect various types of strain from small strain (<5%) to large strain (10-200%) area and distortion motion with excellent sensitivity. When the content of FTS was increased, the elasticity of the composite decreased and the conductivity increased, showing a stable response signal according to the strain in the TPU-FTS composite having an appropriate FTS content (~43 wt%). This can be explained by the reorganization of repetitive conduction pathways without permanent structural destruction of the composite in the region of the optimum FTS content in the TPU-FTS composite. The simple fabrication of strain sensors based on non-traditional resistance sensing materials such as iron(III) sulfonate complexes is expected to have applications in various sensor fields.

본 연구에서는 열가소성 폴리우레탄(TPU)과 iron(III) p-toluenesulfonate(FTS) 복합체의 스트레인 센서 응용을 조사하였다. 일반적으로 FTS는 전도성 고분자의 중합을 위한 전도성 단량체의 산화-커플링 반응 산화제로 활용되어 왔다. 본 연구에서는 FTS를 스트레인에 의한 전기저항 변화를 발현하는 활성 성분으로 고려해 본 결과, TPU-FTS 복합체 기반 스트레인 센서는 작은 변형(<5%)에서 큰 변형 영역까지(10~200%) 우수한 민감도로 감지할 수 있었다. TPU-FTS 복합체에서 FTS 함량을 증가시키면 복합체의 신축성은 감소하나 전기전도도는 증가한다. 실험한 범위에서 43%의 FTS를 사용하였을 때, 변형율에 대한 응답신호가 안정적이었다. 이 영역에서 영구적인 구조 파괴없이 전도 경로가 재구성되었기 때문이라고 생각된다. 철(III) 술포네이트 착화합물과 같은 비전통적인 전기저항 감지 재료를 기반으로 하는 스트레인 센서의 간단한 제작은 다양한 센서 분야의 응용 가능하리라 예상한다.

In this study, p-toluenesulfonate (FTS) is considered as an active component for a strain sensor that exhibits changes in electrical resistance due to strain for the first time. The TPU-FTS composite-based strain sensor can detect various types of strain from small strain (<5%) to large strain (10-200%) area and distortion motion with excellent sensitivity. The simple fabrication of strain sensors based on non-traditional resistance sensing materials such as iron(III) sulfonate complexes is expected to have applications in various sensor fields.

Keywords: strain sensor, iron(III) sulfonate complex, thermoplastic polyurethane, elastomer composite, conductive polymer.

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (NRF-2019R1I1A3A01054826).

The authors declare that there is no conflict of interest.

Flexible and stretchable electronics have become among the most important components in systems utilizing deformation as a platform of motion detection. These studies are applicable in the field of biomedical, energy and the robotics. In particular, thye area of human locomotion-machines interfaces, detection and quantification has been drawn attention.1-3 There has been a wide array of modifications on experimental designs and fabrication processes of these materials in order to obtain enhanced performance for a device, with materials playing a big part in this modification. In the case of stretchable and flexible devices, have consistently been investigated that the constituents making up the sensing materials4-11 and the matrix polymer10-16 that is subject to the mechanical deformations. Literatures have summarized a wide array of materials that can range from metals, semiconductors to intrinsic conducting polymers (ICPs) for the sensing components and from various thin films like PET to fabrics for the matrix.17,18 Some methods of fabrication can be complicated, requiring precise manipulations and employing heavily researched components. Focus of studies can range from creating novel materials, improving or enhancing properties, tunability of already established functionality, to introduction of facile methods and aids in analysis of experimental methods.19-22

Despite the large developments in the field of strain sensors, the device still is subject to drawbacks and challenges. In the case of the resistive-type, the strain sensors still is subject to any one of the following problems: large hysteresis, non-linear response, and irreversibility.1,17,18 Factors such as the rearrangement of fillers or sensing materials may cause the discrepancies in the strain-response relationship. Such occurrence is common with sensing materials that are percolated.1,8,17,18 In the case of the response trend always being exponential, such behavior can be attributed to crack propagation and tunneling effect. In the case of linearity, a good linearity can aid in ease of calibration, predictability and is ideal for processing of data. Also, another characteristic, the stability, remains to be one of the issues faced by wearable sensors, both chemical as well as mechanical in which the sample must undergo repetitive deformation. The stability issue can arise from either device failure or the degradation of the material itself.23

In the study of strain sensors, it is also substantial to have a familiarity in resistance-strain behaviors. Most resistive-strain sensors employ a system where there is conductive filler on, within or all throughout a substrate. The filler content influences greatly the electromechanical properties and a special network configuration sometimes becomes necessary. These makes the study and analysis of stretchable electronics or conductors a difficult task.24 Our previous study had presented the electromechanical capability of percolated networks of the conducting polymer poly(3,4-ethylenedioxythiophene) (PEDOT) in thermoplastic polyurethane (TPU) to function as strain sensor.8,9 The sensor was able to sense different types of deformation including bending and twisting motions. Several difficulties encountered include stability, which can evidently be described by double peaks in some cases of testing. Other common problems included the presence of both positive and negative strain effects. A positive strain effect is characterized by the decrease of the resistance corresponding to the decrease also of strain upon release. However, there are instances when the resistance increases after some strain value, even if when the strain is decreasing. Such behavior is still not fully understood.25 We can infer then that at this case, the motion does not directly correspond with the resistance. It is therefore scientifically encouraged that an alternative or facile method of creating a stretchable motion sensing material, which can also improve stability, be introduced.

In this study, the sensing capability of a strain sensor made with an elastomer substrate and a metal complex are presented. Iron (III) p-toluenesulfonate (FTS), commercially available in its hydrated form, is a chemical substance that is used as an oxidant and dopant in the polymerization of ICPs such as PEDOT. FTS had always been used as initial preparation reagent and does not fit in any category of the sensing materials commonly known to researchers in the composites strain sensor field, would it be on the scope of resistive-type or capacitive-type sensors. Furthermore, no report has been done on the ability of FTS in sensing and detecting motion when integrated in an elastomeric substrate such as TPU. The TPU-FTS sensor was then investigated on its sensing ability by subjecting it to different deformations including small strains (<5%). The effect of not washing off the unreacted FTS on PEDOT-based strain sensor was investigated to see if the stability of the PEDOT-based sensor would be improved.

Reagents and Materials. TPU (Mn=20000 g/mol, polyol= polyester type; Neothane, 5285AP, Dongsung Chemical Co., Busan, Korea, density=1.19 g/cm3, 100% modulus=55 kg/cm2, elongation >500%) was used as the sensor substrate. FTS (Sigma-Aldrich, St. Louis, MO, USA), an oxidant, was used as the sensing material. 3,4-ethylenedioxythiophene (EDOT, Sigma-Aldrich, St. Louis, MO, USA) was used as the monomer for PEDOT. The aforementioned materials were used without further purification. THF (Samchun Pure Chemical Co., Seoul, Korea) was used to dissolve the oxidant and substrate; this chemical was used as received.

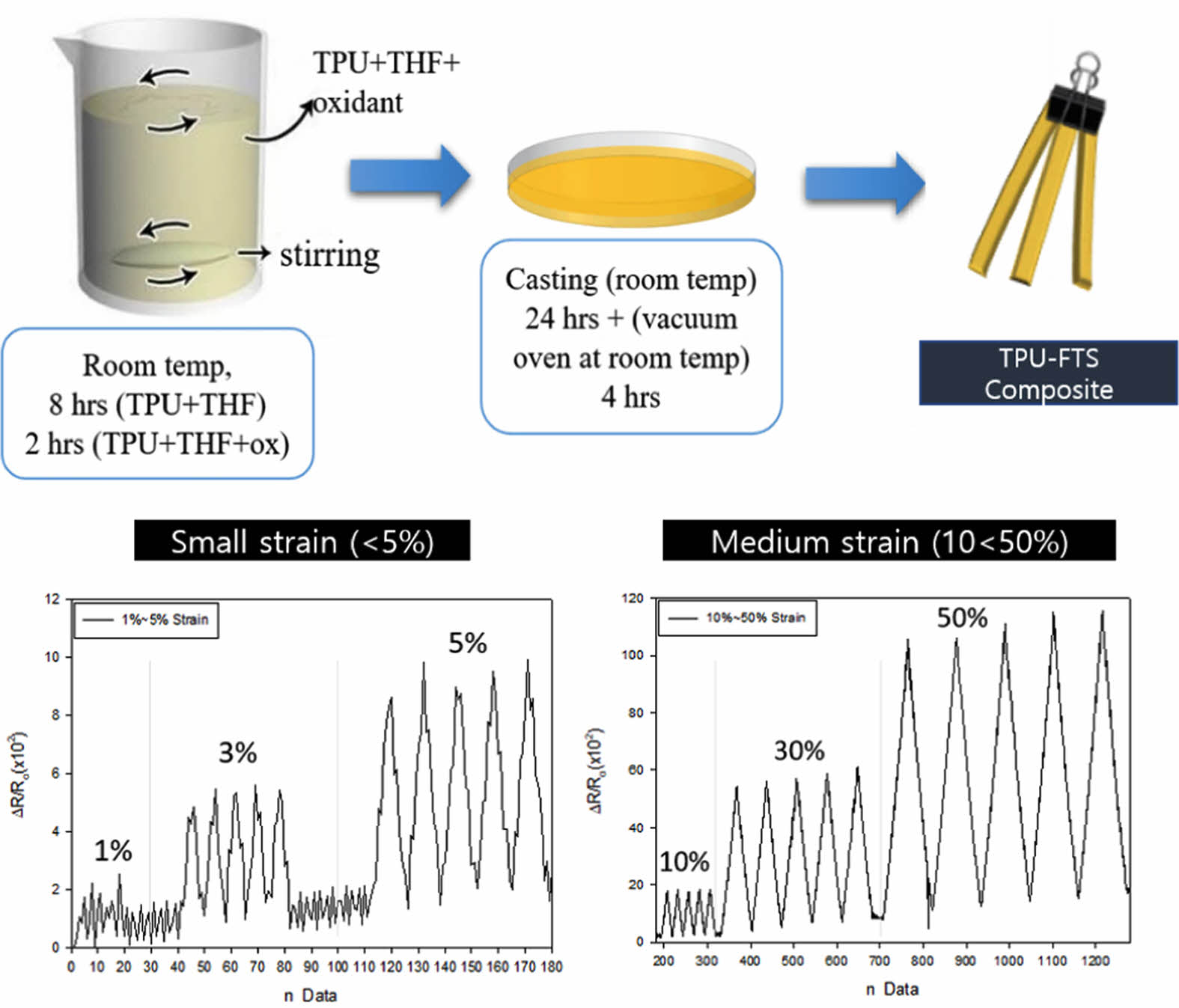

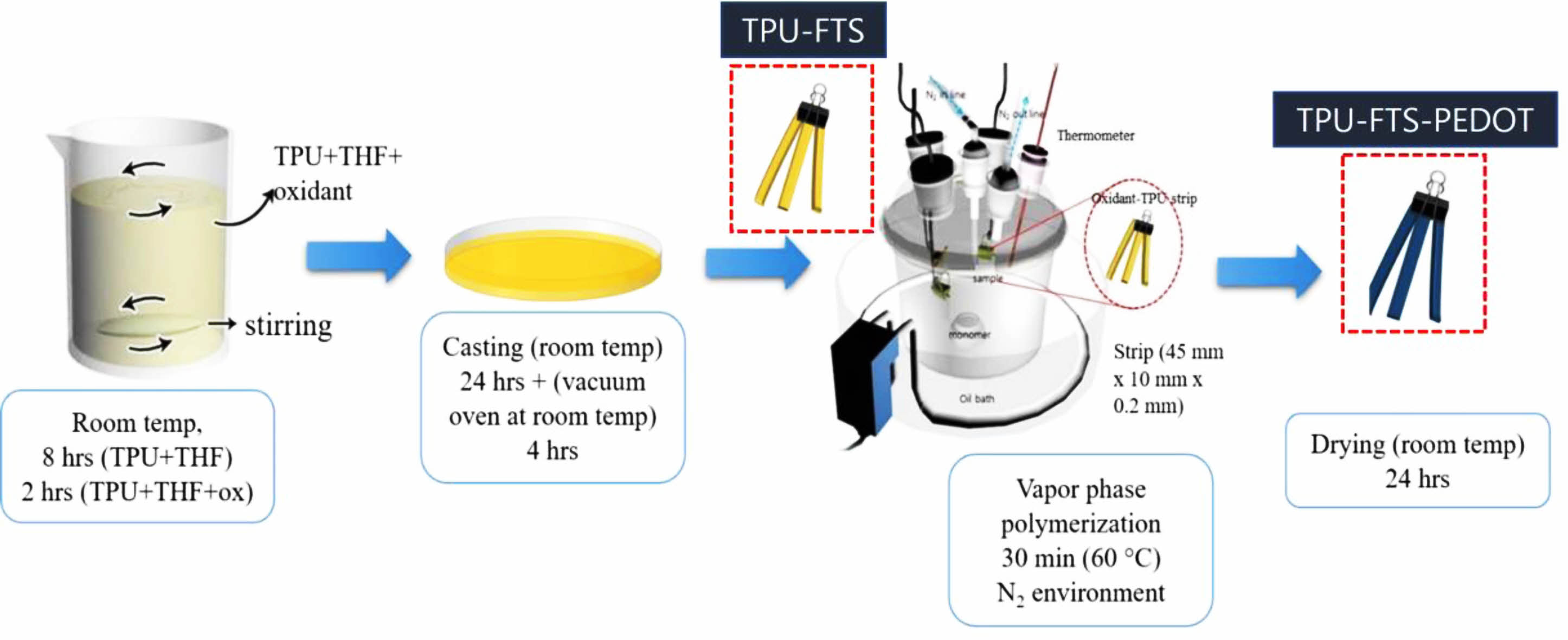

Fabrication of Strain Sensor Based on TPU-FTS and TPU-FTS-PEDOT Composites. 10 wt% TPU was dissolved in the THF solvent for 10 h under continuous stirring at room temperature. FTS was then added into the TPU-THF mixture and was allowed to be dissolved for two hours under continuous stirring. The compositions of the FTS in the non-volatile mixture of TPU and FTS, were 10, 25, 43, 50, and 75 wt%. The composition calculation is based only on the sum of the final solid components, TPU and FTS whereas the previous calculations involved the mass of the solvent. The mixtures were each then poured and casted in a petri dish. The solvent was allowed to be evaporated at room temperature for 24 hours and at the vacuum oven for at least four hours to ensure drying and solidification of the mixture. The final thickness is reduced to 0.2±0.03 mm. Rectangular strips of dimensions 40 mm×10 mm were cut from the cast and were considered as the final products to be tested for their sensing capabilities. TPU-FTS-PEDOT is prepared by an additional vapor phase polymerization (VPP) process to the TPU-FTS composite. A VPP reaction chamber with an N2 inlet/outlet and a thermometer was prepared. Prior to polymerization, N2 was allowed to flow into the reactor at a flow rate of 6 mL/s. As soon as the monomer EDOT was placed at the bottom of the VPP reaction chamber, the cut TPU-FTS elastomer strips were transferred into the reaction chamber and polymerization took place at a maintained internal temperature of 60 °C for 30 min. The prepared TPU-FTS-PEDOT composite did not undergo additional washing process. The preparation of TPU-FTS and TPU-FTS-PEDOT composites in this study is shown in Scheme 1.

Scheme 1. Schematic illustration showing the fabrication of TPU-FTS and TPU-FTS-PEDOT composite.

Characterization of TPU-FTS-based Strain Sensor. The cross-sectional morphologies of the TPU-FTS-based strain sensor were analyzed using field emission - scanning electron microscope (FE-SEM, TESCAN, MIRA LMH, Czech Republic). The tensile stress and elongation properties of the prepared samples were measured using a universal testing machine (UTM, QM100T Qmesys, Korea) at a tensile loading rate of 10 mm/min. Deformations were induced by using a home-made multi-purpose flexibility test machine (IPEN Co., Korea). Resistance variations were measured with an inductance-capacitance-resistance (LCR) meter. The direct current (DC) resistance was measured at various strain values that were categorized as small strains (1-10% strain) and large strains (10-200%). The effect of the unwashed FTS on conductive polymer (CP)-based sensor were observed, and the curve characteristics of the strain sensors were visually compared.

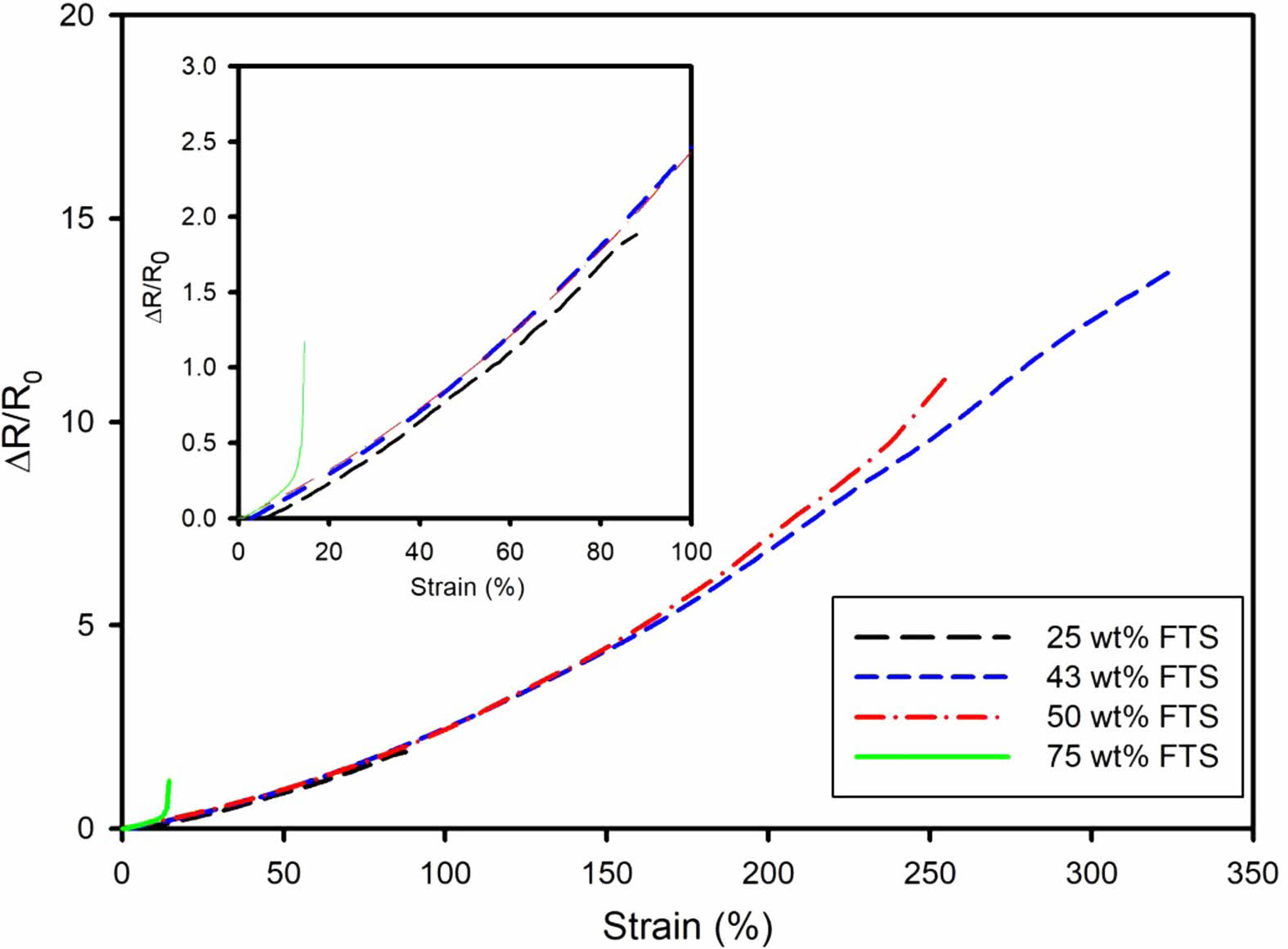

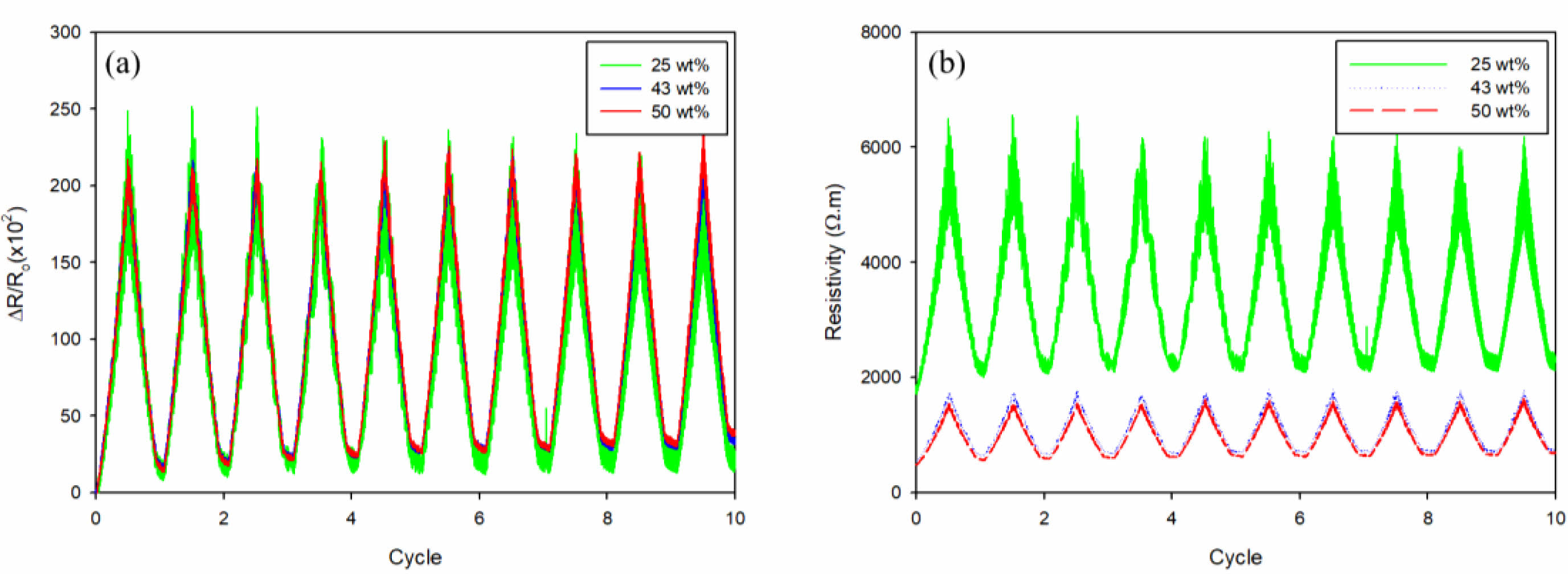

Electromechanical Properties of the TPU-FTS Composites as a Strain Sensor. The TPU-FTS composites made with different concentrations of the FTS were subjected to uniaxial stretching to the multi-purpose flexibility test machine under the limit of 145 mm, which corresponds to 383% strain. Figure 1 shows the relative change of the resistance with respect to strain. It can be observed that the curves of 25 wt% FTS and 75 wt% FTS are cut before and near the 100% strain, respectively. Two different issues have manifested in the two samples. The 25 wt% FTS has reached a very high resistance that is beyond the limit of the LCR meter (99.9 MΩ). The 75 wt% FTS on the other hand, is mechanically destroyed and cut due to poor mechanical property. Nonetheless, it can be observed that 25 wt% FTS, especially, 43 wt% FTS and 50 wt% FTS trace the same path with increasing strain up to about 150% strain. To support this, 25 wt% FTS, 43 wt% FTS, and 50 wt% FTS were subjected to stretch-release cycles at 100% strain.Figure 2(a) displays an overlap of curves, showing that the concentration has not much effect on the response within this strain level. The resistivity (Figure 2(b)), however, decreases with increasing oxidant concentration, suggesting that the conductivity might have come from the FTS, which has never been reported to be conductive. In addition, the curves generated exhibit sharp peaks and stable curve paths. There is no presence of shoulder peaks, which often times occur on conducting polymer-based sensors.26,27 It can be seen that the resistance change of TPU-FTS composites is about 1/4 smaller than that of the existing PEDOT-TPU composite8 in which the conductive polymer PEDOT is composited in TPU matrix under the same conditions. Nevertheless, the TPU-FTS composite of this paper may shows sufficient potential as a sensor since the process for making the composite does not go through the complicated steps through vapor phase polymerization for making previous PEDOT-TPU composite.

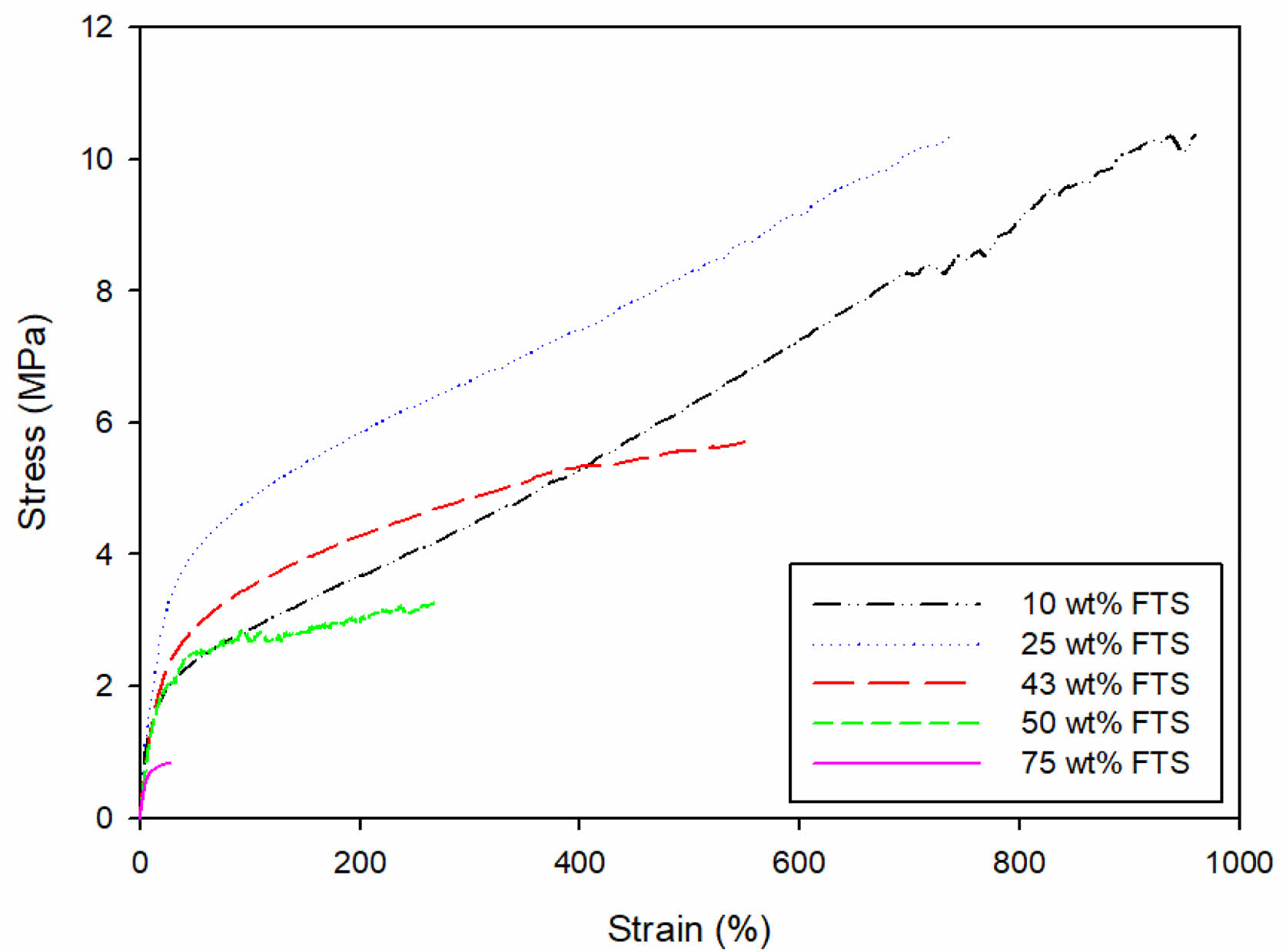

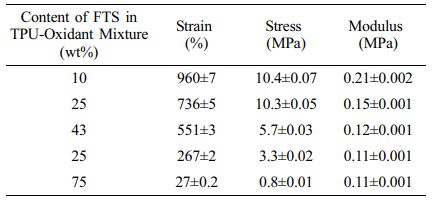

The sensors were also subjected to stress-strain (S-S) test by using UTM as shown in Figure 3. 10 wt% FTS showed the most elastomeric behavior. It can also be observed that stretchability decreases with increasing FTS concentration as expected. More details on mechanical property values calculated from this S-S curves are summarized in Table 1.

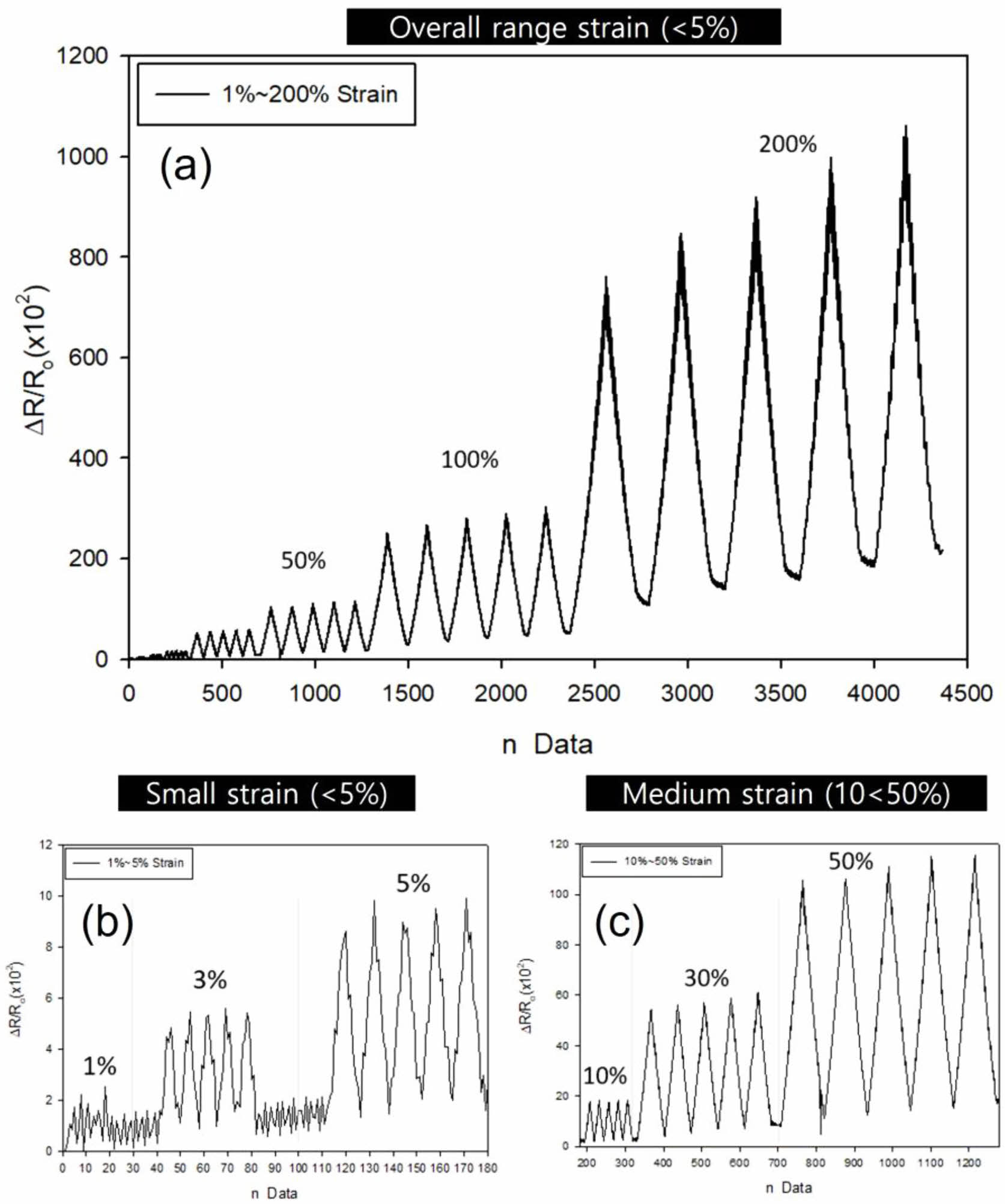

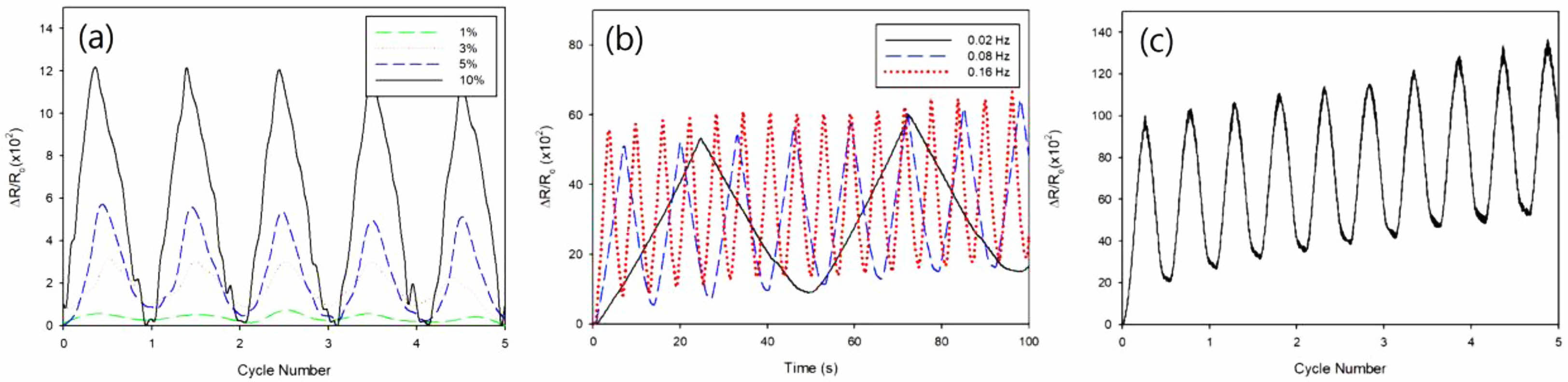

TPU-FTS Composite as a Strain Sensor Characteristic Curves at Different Deformations. In this experiment, the 43 wt% FTS sensor was tested of its capability in sensing stretch-release cycles that include both small (1-10%) and large (10% ↑) strain levels. Our previous experiment of PEDOT-TPU sensor has its application set on large strains.8,9 At smaller strain levels, detection of the motion becomes more difficult. In the case of TPU-FTS sensors, however, the curves in Figure 4 display that the wide ranges of strain can effectively be detected from small (Figure 4(b): <5%), and large ranges (Figure 4(a, c): 10-200%).

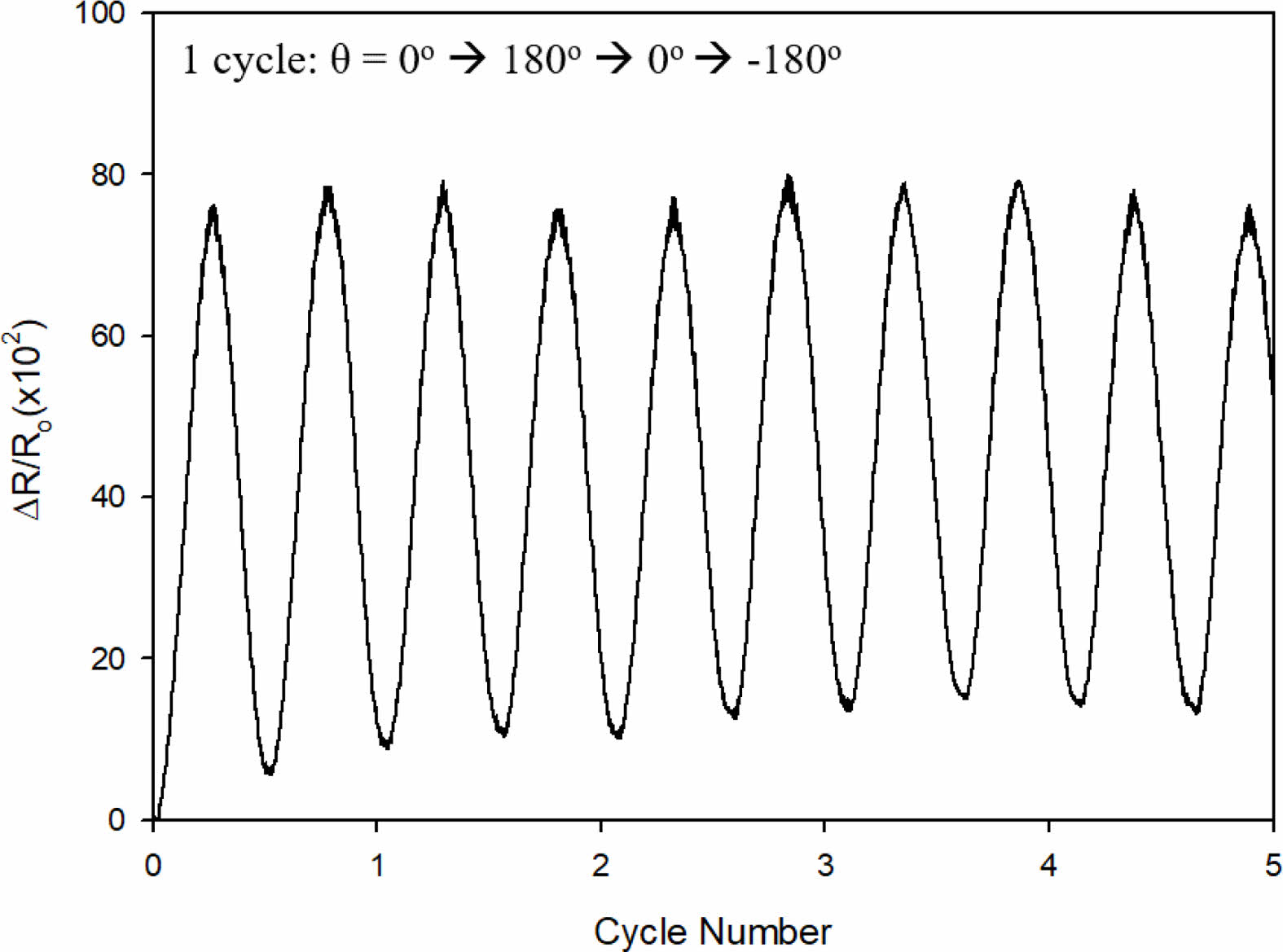

With the visibly sharp peaks obtained during stretch-release cycles, the sensor was also tried on sensing twisting motions. Figure 5 shows the relative resistance during the twisting of TPU-FTS sensor. In this curve, every peak corresponds to 180° rotation. The curve showed that regardless of direction, the curve path is smooth and the same. In comparison with the twisting curve of PEDOT-TPU sensor from our previous study,8 there is more uniformity in the case of TPU-FTS, especially since the deformation was ran at uniform speed and it was successfully exhibited by the TPU-FTS composite as a strain sensor. Such uniformity is ideal, especially since inconsistency of detection of motion may cause misreading which could be detrimental in actual application.

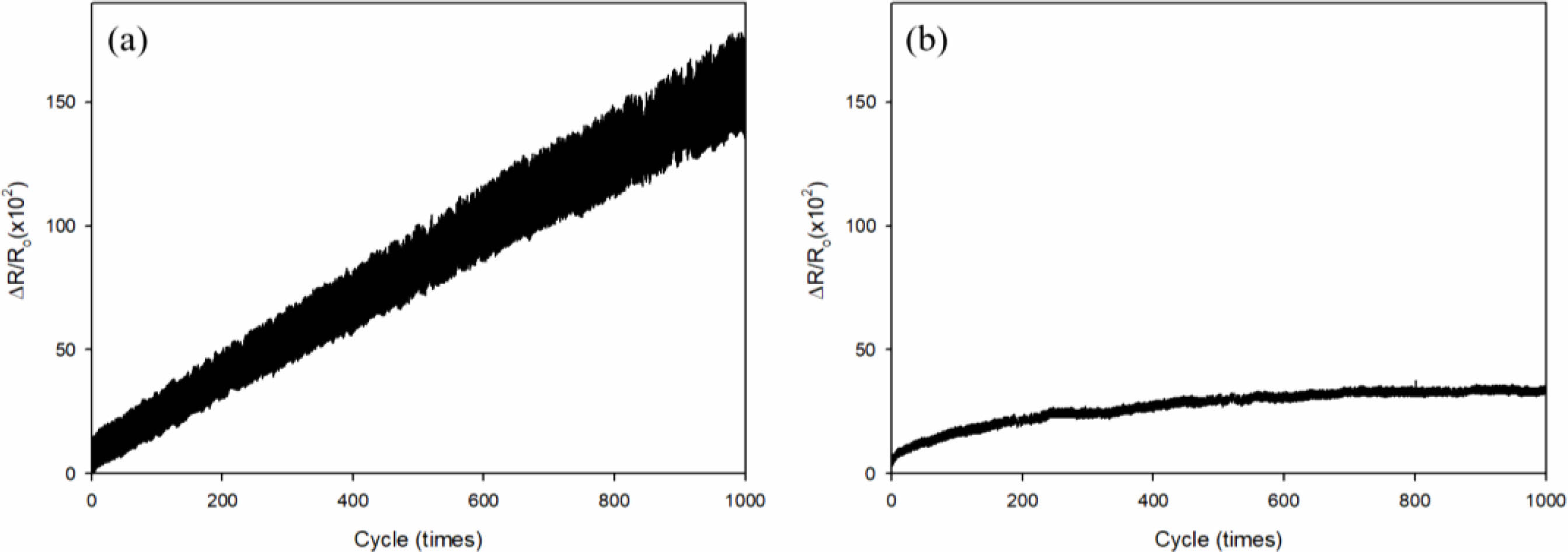

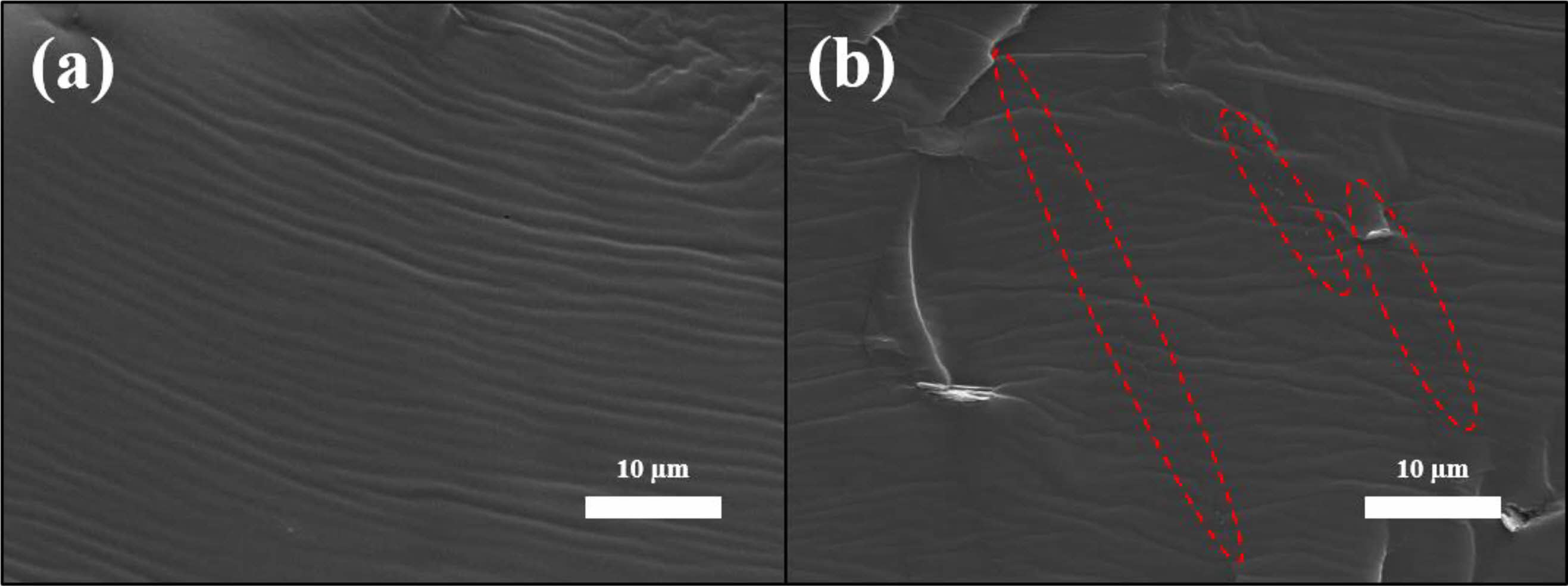

The durability of the TPU-FTS sensor was also studied by subjection to 1000 cycles at 10% strain (see Figure 6). The curve is compared with the CP-based sensor. The relative resistance at 1000 cycles of stretch-release are compared for TPU-FTS (Figure 6(a)) and its counterpart that has undergone vapor phase polymerization into PEDOT to form the TPU-FTS-PEDOT composite reported our previous preparation protocol8 (Figure 30(b)). In TPU-FTS, the sensor had a linear and steady increase of relative resistance that differed greatly with that of TPU-FTS-PEDOT which displayed a gradual increase which eventually plateaued. The curve behavior of the CP-based sensor can be attributed to the destruction and subsequent formation of interfaces between the substrate and the conducting material.24 This can support that TPU-FTS case would have a steady increasing response with increasing number of cycles because the dependence of response would concentrate on the FTS only and on the TPU matrix. Although the mechanism of conduction of TPU-FTS sensor is still unclear, the increase in response can be explained by the physical disintegration of the TPU matrix with increasing number of cycles. In Figure 7, SEM images of TPU-FTS composite that are not used (Figure 7(a)) and had undergone 5000 cyclic stretching at 10% strain (Figure 7(b)) are provided. There is the presence of thin cracks that line along the cross-section, suggesting that the increase in response could have resulted from physical destruction of the composite itself (Figure 7(b)), especially with no other forms of polymer network within that can aid in holding the physical structure of the composite together.

Stabilizing Effect on the Response of Residual FTS in CP-based Composite as a Sensor. Considering the aforementioned performance of TPU-FTS based sensor, the effect of not washing off the unreacted FTS in CP-based sensors, particularly, PEDOT based sensors were also investigated. The fabrication of TPU-FTS-PEDOT sensor follows the method in Scheme 1 similar process without washing step.8 As previously mentioned, detection of small strains is difficult in the case of CP-based sensor.8,9 Surprisingly, it can be clearly seen that TPU-FTS-PEDOT composite based sensor can detect the small strains 1-10% as shown in Figure 8(a), showing that the curves have been stabilized enough so that detection of the strain can be distinguishable from just noise. The peaks of relative resistance retained their sharp features regardless of the speed of the cyclic loading as shown in Figure 8(b). In Figure 8(c), twisting motions also resulting in uniform peaks and there is no presence of shoulder peaks, which can occur with composite sensors often regarded as the result of competing destruction and reconstruction of the conducting pathways at loadings24,28 confirming good response-strain relationship.

The relative resistance curves of FTS containing composite based sensor have shown that it is capable of sensing and may have potential for further studies and development in the strain sensor field. Despite having demonstrated a novel finding, FTS still can have issues and drawbacks. FTS is an oxidant which can be very reactive and can get easily affected by drastic changes in the environment. This issue will also be related to its degradability and reliability as a function of long time. Nonetheless, the capability of a nonconventional sensing material has been demonstrated in this study and the introduction to facile fabrication of the sensor with less demand for components and filler requirements may help future researchers integrate this concept to address the challenges in the strain sensor field, particularly in the scope of the composite strain sensors.

|

Figure 1 Relative resistance-strain curves of TPU-FTS sensors as a function of FTS concentrations. |

|

Figure 2 (a) Resistance variation; (b) resistivity curves of the TPU-FTS sensors of different composition during cyclic stretching/releasing at 100% strain (stretching rate=releasing rate=2.4%/s). |

|

Figure 3 Stress-strain curves for TPU-FTS composites prepared with different concentrations of FTS oxidants. |

|

Figure 4 Resistance variation curve of the TPU-FTS strain sensor during 5 cyclic stretching/releasing per strain level from 1% to 200 % strain recorded continuously (stretching rate=releasing rate= 2.4%/s). |

|

Figure 5 TPU-FTS strain sensor response toward twisting motion. The sensor response during twisting was measured while twisting 360o over 1 cycle |

|

Figure 6 Electrical resistance variation of (a) TPU-FTS; (b) TPU-FTS-PEDOT with repeated 1000 stretching and releasing cycles at 10% applied strain |

|

Figure 7 SEM cross-section images of (a) unused TPU-FTS; (b) used TPU-FTS at 5000× magnification |

|

Figure 8 Typical sensing performance of TPU-FTS-PEDOT composite based sensor (a) resistance variation curve of the sensor during cyclic stretching/releasing at 1, 3, 5, and 10% (stretching rate=releasing rate=2.4%/s); (b) real-time typical relative resistance-strain curve as a function of strain speed; (c) response to twisting motion. |

|

Table 1 Summary of Mechanical Properties of TPU-FTS Sensors Prepared as a Function of FTS Concentrations |

Iron(III) p-toluenesulfonate, which is usually utilized as an oxidant for polymerization of some conducting polymers has been used in this study as a sensing component, a concept which is still unexplored in the strain sensor field. Electromechanical tests have shown that TPU-FTS sensor can sense various forms of deformation, ranging from small strains to large strains, as well as twisting motions. Increasing the amount of FTS reduces the stretchability of the sensor and increases its conductivity. The visually stable curves of TPU-FTS sensor show that it has good response-strain relationship. This can be explained by the absence of competing destruction and reconstruction of conducting pathways at cyclic loadings. By not washing off the residual FTS in CP based sensors, the stabilizing effect can be observed and this was successfully demonstrated at different motions by sensors with PEDOT. However, for actual application of the sensor, further investigation should be made on its chemical stability and degradation. Nonetheless, the facile fabrication of sensor based on a non-conventional sensing material with the benefit of less demanding filler requirements may just be a small step towards addressing the current challenges in the strain sensor field, as well as in opening more opportunities for diversity of properties that can be enhanced and more areas that can be subject for tunability.

- 1. Amjadi, M.; Kyung, K.-U.; Park, I.; Sitti, M. Stretchable, Skin-Mountable, and Wearable Strain Sensors and Their Potential Applications: A Review. Adv. Funct. Mater. 2016, 26, 1678-1698.

-

- 2. Elgeneidy, K.; Neumann, G.; Jackson, M.; Lohse, N. Directly Printable Flexible Strain Sensors for Bending and Contact Feedback of Soft Actuators. Front. Robot. AI 2018, 5, 2.

-

- 3. Liu, Y.; Wang, H.; Zhao, W.; Zhang, M.; Qin, H.; Xie, Y. Flexible, Stretchable Sensors for Wearable Health Monitoring: Sensing Mechanisms, Materials, Fabrication Strategies and Features. Sensors 2018, 18, 645.

-

- 4. Hong, S. K.; Yang, S.; Cho, S. J.; Jeon, H.; Lim, G. Development of a Waterproof Crack-Based Stretchable Strain Sensor Based on PDMS Shielding. Sensors 2018, 18, 1171.

-

- 5. Jeon, H.; Hong, S. K.; Kim, M. S.; Cho, S. J.; Lim, G. Omni-purpose Stretchable Strain Sensor Based on a Highly Dense Nanocracking Structure for Whole-body Motion Monitoring. ACS Appl. Mater. Interfaces 2017, 9, 41712-41721.

-

- 6. Xian, H. J.; Cao, C R.; Shi, J. A.; Zhu, X. S.; Hu, Y. C.; Huang, Y. F.; Meng, S.; Gu, L.; Liu, Y. H.; Bai, H. Y.; Wang, W. H. Flexible Strain Sensors with High Performance Based on Metallic Glass Thin Film. Appl. Phys. Lett. 2017, 111, 121906.

-

- 7. Liao, X.; Yan, X.; Lin, P.; Lu, S.; Tian, Y.; Zhang, Y. Enhanced Performance of ZnO Piezotronic Pressure Sensor through Electron-Tunneling Modulation of MgO Nanolayer. ACS Appl. Mater. Interfaces 2015, 7, 1602-1609.

-

- 8. Losaria, P. M.; Yim, J.-H. A Highly Stretchable Large Strain Sensor Based on PEDOT-thermoplastic Polyurethane Hybrid Prepared via in situ Vapor Phase Polymerization. J. Ind. Engin. Chem. 2019, 74, 108-117.

-

- 9. Losaria, P. M.; Yim, J.-H. Enhancement of Strain-Sensing Performance through Gas Phase Incorporation of Siloxane into Thermoplastic Polyurethane-Conducting Polymer Composite. Macromol. Chem. Phys. 2020, 2000155.

-

- 10. Palicpic, C. M.; Khadka, R.; Yim, J.-H. Electromechanically Durable Graphene Oxide-Embedded Elastomer via Simultaneous Corporation of Siloxane/Polyol Based on the Dual Secondary Bond Architecture. ACS Appl. Polym. Mater. 2022, 4, 2614-2625.

-

- 11. Park, D.; Park, Y.-K.; Selvam, S.; Yim, J.-H. Styrene-based Ternary Composite Elastomers Functionalized with Graphene Oxide-polypyrrole Under Iron(III)-alkyl Benzenesulfonate Oxidants for Supercapacitor Integrated Strain Sensor System. J. Energy Storage 2022, 51, 104543.

-

- 12. Kim, K.-H.; Jang, N.-S.; Ha, S.-H.; Cho, J. H.; Kim, J.-M. Highly Sensitive and Stretchable Resistive Strain Sensors Based on Microstructured Metal Nanowire/Elastomer Composite Films. Small 2018, 14, 1704232.

-

- 13. Amjadi, M.; Turan, M.; Clementson, C. P.; Sitti, M. Parallel Microcracks-based Ultrasensitive and Highly Stretchable Strain Sensors. ACS Appl. Mater. Interfaces 2016, 8, 5618-5626.

-

- 14. Khan, U.; May, P.; O’Neill, A.; Coleman, J. N. Development of Stiff, Strong, Yet Tough Composites by the Addition of Solvent Exfoliated Graphene to Polyurethane. Carbon 2010, 48, 4035-4041.

-

- 15. Lin, L.; Liu, S.; Zhang, Q.; Li, X.; Ji, M.; Deng, H.; Fu, Q. Towards Tunable Sensitivity of Electrical Property to Strain for Conductive Polymer Composites Based on Thermoplastic Elastomer. ACS Appl. Mater. Interfaces 2013, 5, 5815-5824.

-

- 16. Costa, P.; Silva, J.; Ansón-Casaos, A.; Martinez, M. T.; Abad, M. J.; Viana, J.; Lanceros-Mendez, S. Effect of Carbon Nanotube Type and Functionalization on the Electrical, Thermal, Mechanical and Electromechanical Properties of Carbon Nanotube/styrene-butadiene-styrene Composites for Large Strain Sensor Applications. Composites Part B 2014, 61, 136-146.

-

- 17. Borghetti, M.; Serpelloni, M.; Sardini, E. Printed Strain Gauge on 3D and Low-Melting Point Plastic Surface by Aerosol Jet Printing and Photonic Curing. Sensors 2019, 19, 4220.

-

- 18. Souri, H.; Banerjee, H.; Jusufi, A.; Radacsi, N.; Stokes, A. A.; Park, I.; Sitti, M.; Amjadi, M. Wearable and Stretchable Strain Sensors: Materials, Sensing Mechanisms, and Applications. Advan. Intel. Sys. 2020, 2, 2000039.

-

- 19. Jiang, Y.; Liu, Z.; Matsuhisa, N.; Qi, D.; Leow, W. R.; Yang, H.; Yu, J.; Chen, G.; Liu, Y.; Wan, C.; Liu, Z.; Chen, X. Auxetic Mechanical Metamaterials to Enhance Sensitivity of Stretchable Strain Sensors. Adv. Mater. 2018, 30, 1706589.

-

- 20. Shyu, T. C.; Damasceno, P. F.; Dodd, P. M.; Lamoureux, A.; Xu, L.; Shlian, M.; Shtein, M.; Glotzer, S. C.; Kotov, N. A. A Kirigami Approach to Engineering Elasticity in Nanocomposites Through Patterned Defects. Nat. Mater. 2015, 14, 785-789.

-

- 21. Vandeparre, H.; Liu, Q.; Minev, I. R.; Suo, Z.; Lacour, S. P. Localization of Folds and Cracks in Thin Metal Films Coated on Flexible Elastomer Foams. Adv. Mater. 2013, 25, 3117-3121.

-

- 22. Chortos, A.; Lim, J.; To, J. W. F.; Vosgueritchian, M.; Dusseault, T. J.; Kim, T.‐H.; Hwang, S.; Bao, Z. Highly Stretchable Transistors Using a Microcracked Organic Semiconductor. Adv. Mater. 2014, 26, 4253-4259.

-

- 23. Heikenfeld, J.; Jajack, A.; Rogers, J.; Gutruf, P.; Tian, L.; Pan, T.; Li, R.; Khine, M.; Kim, J.; Wang, J.; Kim, J. Wearable Sensors: Modalities, Challenges, and Prospects. Lab Chip 2018, 18, 217-248.

-

- 24. Deng, H.; Ji, M.; Yan, D.; Fu, S.; Duan, L.; Zhang, M.; Fu, Q. Towards Tunable Resistivity-strain Behavior Through Construction of Oriented and Selectively Distributed Conductive Networks in Conductive Polymer Composites. J. Mater. Chem. A 2014, 2, 10048-10058.

-

- 25. Duan, L.; Fu, S.; Deng, H.; Zhang, Q.; Wang, K.; Chen, F.; Fu, Q. The Resistivity-strain Behavior of Conductive Polymer Composites: Stability and Sensitivity. J. Mater. Chem. A 2014, 2, 17085-17098.

-

- 26. Kim, Y. J.; Kang, H. J.; Moerk, C. T.; Lee, B.-T.; Choi, J. S.; Yim, J.-H. Flexible, Biocompatible, and Electroconductive Polyurethane Foam Composites Coated with Graphene Oxide for Ammonia Detection. Sens. Actuators, B 2021, 344, 130269.

-

- 27. Park, D.-D.; Yim, J.-H. Preparation of the Electro-Mechanically Durable rGO-SEBS Composite Elastomer and Its Application as a Strain Sensor. Polym. Korea 2022, 46, 81-87.

-

- 28. Kingston, C.; Zepp, R.; Andrady, A.; Boverhof, D.; Fehir, R.; Hawkins, D.; Roberts, J.; Sayre, P.; Shelton, B.; Sultan, Y.; Vejins, V.; Wohlleben, W. Release Characteristics of Selected Carbon Nanotube Polymer Composites. Carbon 2014, 68, 33-57.

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2024 Impact Factor : 0.6

- Indexed in SCIE

This Article

This Article

-

2022; 46(5): 646-653

Published online Sep 25, 2022

- 10.7317/pk.2022.46.5.646

- Received on May 16, 2022

- Revised on Jun 22, 2022

- Accepted on Jun 22, 2022

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

- Conflict of Interest

Introduction

Experimental

Results and Discussion

Conclusion

- References

Shared

Correspondence to

Correspondence to

- Jin-Heong Yim

-

Division of Advanced Materials Engineering, Kongju National University, 1223-24 Cheonandaero, Cheonan, Chungnam 31080, Korea

- E-mail: jhyim@kongju.ac.kr

- ORCID:

0000-0002-3557-9564

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.