- Effects of Wet Mixing with Three Differing Carbon Black Particle Sizes on the Mechanical Properties of Natural Rubber Composites

Hong Liu*,# , Hui Xu*,# , Yukun Zhou*, and Chuansheng Wang*, **,†

*College of Electromechanical Engineering, Qingdao University of Science & Technology, Qingdao 266061, China

**National Engineering Laboratory of Advanced Tire Equipment and Key Materials, Qingdao University of Science & Technology, Qingdao 266061, China- 세 가지 다른 카본블랙 입자 크기를 적용한 습식 혼합이 천연고무 복합체의 기계적 물성에 미치는 영향

Reproduction, stored in a retrieval system, or transmitted in any form of any part of this publication is permitted only by written permission from the Polymer Society of Korea.

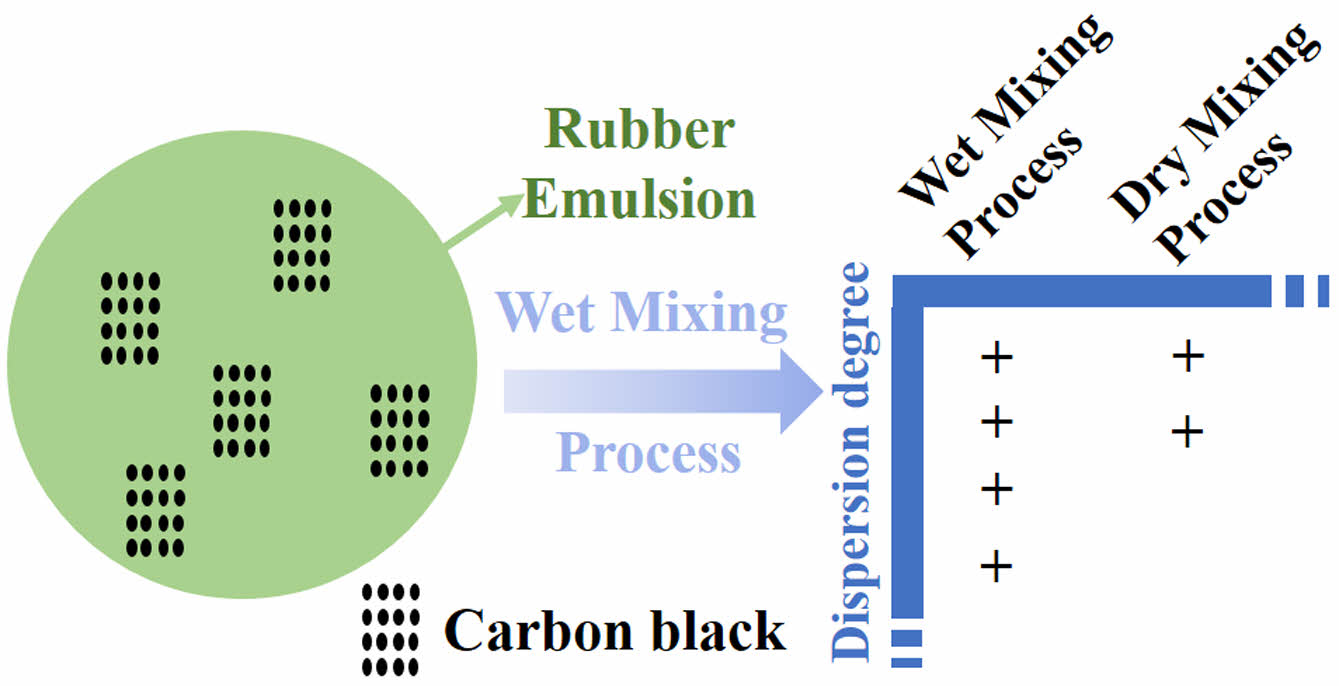

To mitigate the issues of high energy consumption and extended processing times commonly associated with rubber compounding, this study explores the vulcanization characteristics and physico-mechanical properties of rubber composites prepared using the wet mixing method with three different particle sizes of carbon black. Comparative analysis with the conventional dry mixing approach reveals distinct advantages of the wet method depending on the type of carbon black used. For N110, the sieving filtration wet process yields the most favorable overall performance. For N234, both the grinding and sieving filtration wet mixing techniques significantly enhance material properties relative to dry mixing, with negligible differences observed between the two wet methods. For N326, the grinding wet process offers superior comprehensive performance. Additionally, powdered carbon black demonstrates rapid dispersibility in natural latex under wet mixing conditions, which not only shortens processing time but also contributes to improved filler dispersion and overall rubber performance, while realizing the green and low-energy processing of rubber.

The effect of carbon black type on rubber was studied under different processes. Wet mixing saves mixing time and improves the overall performance of rubber. The effect of carbon black particle size on the rubber is very small in the wet process.

Keywords: wet mixing, natural latex, powdered carbon black, pretreatment.

The authors would like to express their sincere thanks to: The work was financially supported by the Nation Natural Science Foundation of China (No.51345006); Shandong Province Natural Science Foundation of China (No. ZR202102180625).

The authors declare that there is no conflict of interest.

Amid the rapid growth of the global rubber industry, the challenges of resource depletion and the growing emphasis on environmental sustainability have driven the development of green, eco-friendly, and stable processing methods for producing high-performance rubber materials.1-3 Natural latex has excellent overall performance, mainly in because it has good film formation, is easily vulcanized and is able to prepare rubber products with excellent elasticity, high strength, high elongation and low creep.4-6 As a crucial reinforcing and filling agent, carbon black plays an indispensable role in the rubber industry, with both industries exhibiting strong interdependence and co-development.7 Yanchen Fang et al. modified cracked carbon black with argon plasma to increase the average fatigue life of the composite by 57%.8 Recently, some researchers have provided a method for the preparation of a wet masterbatch of carbon black, in which the aqueous dispersion slurry of carbon black was mixed with rubber latex after adjusting to the acidity, and then the masterbatch was prepared by coagulation drying.9,10

Wet blending for flocculation method research is mainly divided into the emulsion flocculation method and spray flocculation drying method.10-12

Emulsion flocculation methods include acid flocculation, salt flocculation, electrophoretic flocculation, heating flocculation and mechanical destabilization flocculation.13-16

Xiao et al. introduced silane coupling agents and natural mineral resources kaolin into the wet mixing process of natural rubber emulsion to prepare highly wear-resistant, low-heat-generating natural rubber composite materials. Compared with dry mixing, wet mixing improved the crosslinking density, gas barrier performance, and wear resistance by 24%, 45%, and 9%, respectively.17

Huang et al. prepared graphene oxide/silica/NBR composite materials using a wet mixing and ball milling modification process. Compared with composite materials prepared using a dry mixing process, the tensile product change rate and wear volume change rate were reduced by 35.28% and 16.69%, respectively, while the tear strength was increased by 57.28%.18 Yusof, NH et al. prepared silica-rubber masterbatch by adding different levels of silica to the latex and preparing silica-rubber masterbatch through the latex stage for a more homogeneous distribution of silica in the rubber matrix.19

Yang Jiashun et al. prepared silica/natural rubber masterbatch using solution compounding method. The dispersion of silica in the rubber matrix was improved and the rolling resistance of the composite was reduced.20 Bian et al. used dry ice expansion pre-dispersion flocculation to improve the dispersion of graphene oxide and multi-walled carbon nanotubes in butyl latex to further improve the thermal conductivity of the composites.21 The spray flocculation drying method applied to the mixture containing carbon black can achieve the simultaneous completion of flocculation and drying to prepare masterbatch and achieve good dispersion of carbon black in rubber, but due to the characteristics of carbon black, the mixture needs to be diluted to a very low solid content concentration, for which the water application was increased and the spray drying process was complicated, requiring high-level equipment, yet still producing unstable materials. The emulsion co-sinking method for the preparation of wet kneading rubber uses some flocculants such as acid and alkali, which can cause environmental pollution and affect the performance of the rubber.22 Therefore, this paper adopted a flocculant-free flocculation method to achieve acid-free flocculation, no waste water and superior rubber performance.

In this study, carbon black based masterbatches were prepared via a wet coagulation process. Three types of carbon black—N110, N234, and N326—were evaluated using different treatment methods, including grinding, sieving filtration, and direct use of powdered forms. The resulting masterbatches were characterized in terms of their coagulation behavior and material properties. This work contributes to advancing rubber compounding techniques toward more environmentally friendly and sustainable processing routes.

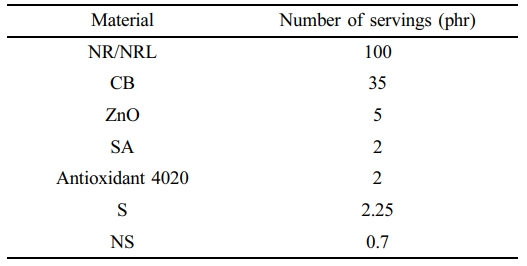

Materials. Natural rubber latex (NRL): dry rubber content of 60%, Hainan Natural Rubber Industry Group Co., Ltd; Natural rubber (STR20): Thailand Shi Dong Rubber Co., Ltd; Carbon black with different particle sizes and structures (CB, N110, N234, N326): Cabot Company; zinc oxide (ZnO), stearic acid (SA), N-tert-butylbenzothiazole-2-sulphenamide (accelerator NS), N-1,3-dimethylbutyl-N'-phenyl-p-phenylenediamine (antioxidant 4020), sulfur (S): Shandong Shangshun Chemical Co., Ltd. The experimental formulations are shown in Table 1.

Sample Preparation. Preparation of Carbon Black Slurry With Different Experimental Methods

: Grinding carbon black: Granulated carbon black samples (100 g each of N110, N234, and N326) were placed in a 1 L ceramic jar of a planetary ball mill and ground at 40 Hz for 0.5 h. After grinding, the compacted carbon black was loosened using an iron rod to break apart agglomerates formed during milling, yielding dry-ground carbon black of different grades. Subsequently, 35 parts by mass of the ground carbon black were mixed with deionized water to achieve a 25 wt% carbon black slurry. The mixture was gently stirred until a homogeneous dispersion was obtained.

Sieving Filtration Carbon Black: Grinding carbon black can reduce both its particle size and structural integrity, which may negatively affect its reinforcing ability in rubber, as the particle structure is closely linked to rubber performance. To preserve the structural characteristics, granulated carbon black was first crushed using a disc grinder and subsequently passed through a 100-mesh screen together with small grinding balls to obtain sieving filtration carbon black. A total of 35 parts by mass of the sieving filtration carbon black was then mixed with deionized water to prepare a slurry with a carbon black concentration of 25 wt%. The mixture was gently stirred until uniform. This treatment did not significantly alter the particle morphology or surface structure compared with the original granulated carbon black; however, it allowed the carbon black to be converted into a fine powder, which facilitated its dispersion during the wet masterbatch preparation process.

Powdered carbon black was obtained as an intermediate product from the carbon black granulation process. To prepare the slurry, 35 parts by mass of powdered carbon black were mixed with deionized water to achieve a carbon black concentration of 25 wt%. Due to the extremely light and porous nature of the powdered carbon black, the resulting slurry exhibited high viscosity and underwent rapid flocculation when mixed with natural latex, leading to poor dispersion of carbon black within the resulting micelles. To address this issue, a diluted slurry with a concentration of 15 wt% was also prepared using the same amount of carbon black and additional water. Compared with granulated carbon black, the powdered carbon black required more time for complete wetting and dispersion in water.

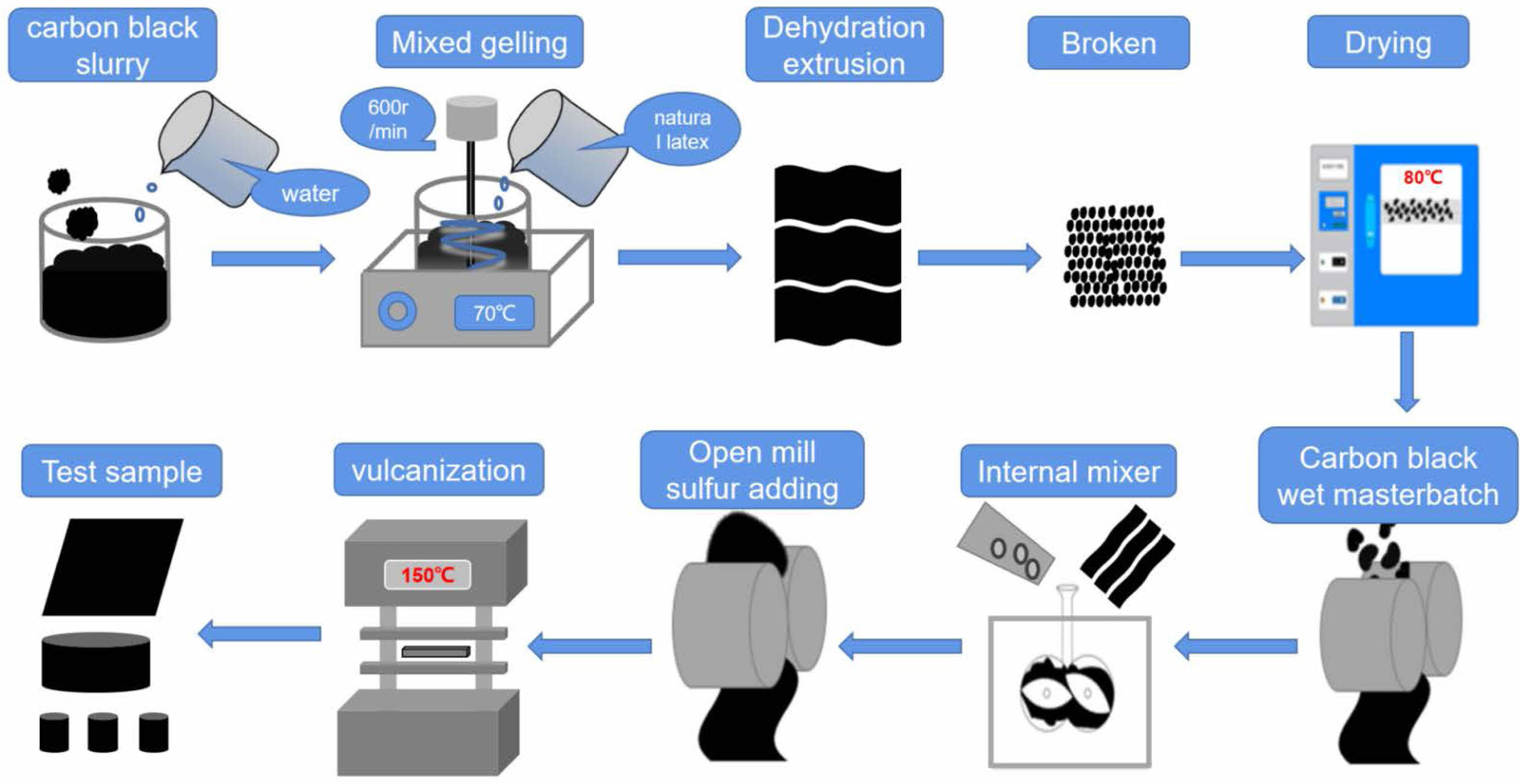

Preparation of Natural Rubber Latex/carbon Black Masterbatch: A total of 140 parts by mass of 25 wt% carbon black slurry and 166.67 parts by mass of 60 wt% natural latex were each placed into separate beakers. The contents of the two beakers were then simultaneously poured into a third beaker to form a carbon black–latex mixture.9 After thorough mixing, the mixture was heated to 70 ℃ and stirred at 600 rpm until it lost fluidity and complete flocculation occurred.23

The flocculated carbon black masterbatch was first fed into a temperature-controlled biconical dewatering extruder set at 60 ℃. Upon extrusion through the outlet die, the rubber was immediately processed using high-speed shear crushing equipment for over 10 s, which converted the material into a powdered form. Finally, the powder was dried in an oven at 80 ℃ until a dry rubber state was achieved.

Mixing and Vulcanization: Dry mixing process: The natural rubber is put into the internal mixer, and CB, ZnO, SA and antioxidant 4020 are added after 1 min. The temperature reaches 145 ℃ after 5 min. The total mixing time is 5 min. After discharging the rubber, the accelerator NS and sulfur are added to the master batch on the open mill.

Wet mixing process: The carbon black masterbatch was introduced into the internal mixer, and the ram was released. After 1 minute of initial mixing, zinc oxide (ZnO), antioxidant 4020, and stearic acid (SA) were added. At 4 min, the temperature of the compound reached 145 ℃, at which point the compound was discharged. The total mixing time was 5 min. Subsequently, the compound was transferred to a two-roll open mill, where sulfur and accelerator NS were incorporated. The rubber compound was then vulcanized at 150 ℃ under a pressure of 11 MPa for a duration of 1.3×T90 to obtain the vulcanized rubber. The experimental process is shown in Figure 1.

Testing and Characterization. Carbon Black Performance Analysis: The particle size, specific surface area and structure of carbon black were related to the performance of carbon black filled rubber. The particle size was determined by the nitrogen adsorption specific surface area method, the structure was characterized by the compression oil absorption value, and the particle size distribution was determined by a disc type centrifugal sedimentation meter. The total specific surface area of carbon black (NSA). The external specific surface area of carbon black (STSA). Oil absorption value (DBP) indicates the sum of the primary structure and secondary structure of carbon black. The primary structure of carbon black (CDBP). D10 indicates that the particle size of carbon black below 10% was less than this value. D50 indicates that the particle size of carbon black below 50% was less than this value. D90 indicates that 90% of the carbon black particles were smaller than this value.

Vulcanization Characteristics: The vulcanization characteristics were tested by a rotorless rheometer (MDR-C, Alpha, USA) according to the standard ISO 6502–2:2018. The test time was 60 min, and the test temperature was 150 ℃.

Payne Effect: The Payne effect was tested by a rubber processing analyzer (RPA2000, Alpha, America). The frequency was 0.01 Hz, the strain range was 0.28-40%, and the temperature was set at 60 ℃.

Mechanical Properties: The tensile test be carried out according to GB/T528-2009. The specimen be cut into dumb-bell shaped specimens and then tested by universal testing machine (INSTRON, 3365B). With the tensile rate of 500 mm/min, five samples of each vulcanized rubber were tested, the amount from which the average value was taken.

Carbon Black Dispersion Analysis: The dispersion value of carbon black in the composite was directly derived by testing the rubber cross-section using a carbon black dispersion analyser (Alpha, USA). The value was calculated according to ASTM D7723. Use the cutter to cut a section of about 5 mm × 8 mm. The dispersion calculation threshold of test method was 23 μm. The volume fraction of filler was 30%, and the exposure time was 40 ms.

Dynamic Mechanical Thermal Analysis: It was measured by a dynamic thermomechanical analyzer (EPLEXOR-150 N, GABO, Germany). The static strain was 5%, the static stress was 70 N, the dynamic strain was 0.25%, the dynamic stress was 60 N, the heating rate was 2 ℃/min and the frequency was 10 Hz.

|

Figure 1 Schematic diagram of CB/NR composites prepared by flocculation-extrusion dehydration wet mixing process. |

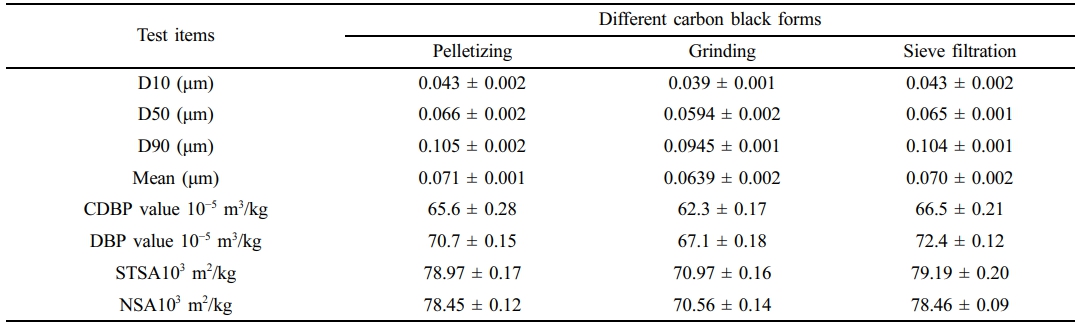

Analysis of the Physical Properties of Carbon Black. The physical properties of N326 carbon black in various forms, including pelletized, grinding and sieving filtration were evaluated, and the results are shown in Table 2. According to the data, both the particle size and structure of the grinding carbon black were reduced compared to those of the pelletized form. This can be attributed to the increased specific surface area resulting from the high energy collisions of the grinding media during the milling process, which disrupted the original structure of the carbon black and thus reduced its particle size and structural integrity. In contrast, due to the absence of strong mechanical collisions, the sieving filtration carbon black exhibited no significant change in overall specific surface area or particle size relative to the pelletized form. However, both the external specific surface area and structural index increased. This phenomenon was likely due to the removal of poorly structured or low-performance regions during the sieving filtration process, effectively enhancing the uniformity and quality of the remaining carbon black particles.24

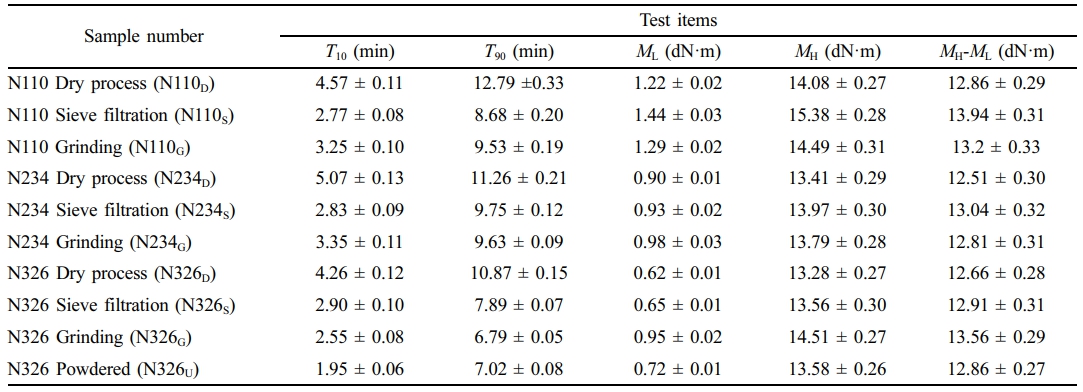

Vulcanization Characteristics. Table 3 presents the vulcanization parameters for rubber composites prepared via both wet and corresponding dry processes using different carbon black treatment methods. For all three grades of carbon black (N110, N234, and N326), the positive vulcanization time (T90) was generally shorter in the wet mixing process compared to the dry mixing process. This reduction in T90 is attributed to the decreased aggregate particle size in the wet mixing rubber, which enhances the decomposition rate of the vulcanization accelerator, thereby accelerating the vulcanization process. T10, which reflects the scorching time of the compound (with higher values indicating better processing safety), was typically lower in the wet mixing process. This is because, in the dry mixing process, carbon black is added in two stages, while in the wet process, the carbon black masterbatch is introduced all at once. Consequently, the temperature of the compound in the wet process increases more rapidly. As sulfur is also added during this phase, the overall heating rate during mixing is higher, making the compound more susceptible to premature vulcanization.

The minimum torque (ML) and maximum torque (MH) obtained from the vulcanization curve represent the compound’s viscosity and stiffness, respectively. MH is associated with the hardness and modulus of the vulcanized rubber, while ML reflects the compound’s flowability. The difference between MH and ML (i.e., MH–ML) is indicative of the crosslink density, which correlates with the number of crosslinking bonds in the polymer matrix.

Focusing on N326 carbon black, the MH–ML value for the wet grinding N326 sample was the highest, showing a 7.1% increase compared to its dry-process. This suggests that although the grinding process reduced both particle size and structural integrity, the reinforcement effect due to particle size reduction outweighed the negative impact of structural loss. As a result, the wet grinding N326 exhibited the highest overall reinforcement and crosslinking density.

In comparison, N326 that was sieving filtration showed no significant reduction in particle size, and its MH–ML value was lower than that of the ground sample. Meanwhile, the powdered N326 sample, due to its extremely low density and poor dispersibility, resulted in uneven carbon black distribution within the rubber matrix, leading to the lowest MH–ML value among the samples studied.

For N110 carbon black, which had the smallest particle size among the three grades studied, the grinding process resulted in only a slight further reduction in particle size. However, an excessively small particle size may exceed the optimal dispersion threshold for the wet mixing process, leading to poor carbon black dispersion within the rubber matrix. Furthermore, the grinding process reduced the structural integrity of the carbon black, diminishing its reinforcing capability. In contrast, the sieving filtration carbon black maintained its particle size while enhancing dispersion due to the synergistic effect of the wet process, thereby improving its reinforcing effect. The positive vulcanization time (T90) for the sieved filtration carbon black in the wet process decreased by 32.1% compared to the dry process, while the MH–ML value increased by 8.4%, indicating that the sieving filtration based wet process yielded the highest crosslink density and the best reinforcing performance for N110 carbon black.25

For N234 carbon black, which had a moderate particle size but the highest structural level among the three types, both the grinding and sieving filtration carbon black in the wet mixing process exhibited a 4.2% increase in MH–ML compared to the dry process. This can be attributed to the fact that the combined reinforcing effect of reduced particle size and structure (from grinding) was approximately equivalent to that of the sieving filtration carbon black, indicating a comparable reinforcement performance for both treatments in the wet process.

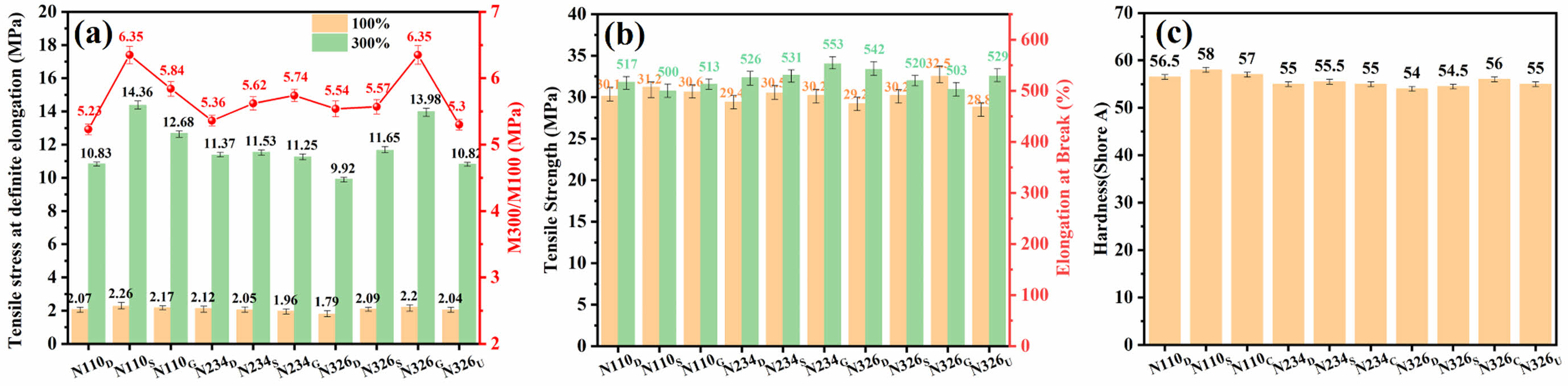

Physical Properties. Figure 2 presents the tensile strength and modulus (M100%, M300%) data for different mixing processes, demonstrating that the physical and mechanical properties were comparatively enhanced through the wet flocculation process. Focusing on N110 carbon black, which exhibited the smallest particle size among the three grades and a DBP structural value of approximately 113 (higher than that of N326), the data indicate that the overall mechanical performance of the sieving filtration carbon black processed via the wet method was superior to both the dry process and the wet process using grinding carbon black. Specifically, compared to the corresponding dry process, the tensile strength and the M300%/M100% ratio increased by 3.65% and 21.4%, respectively.

This improvement can be attributed to the fact that the wet process did not require the use of acid, surfactants, or prolonged drying, thereby preserving the intrinsic properties of the rubber molecular chains and enhancing mechanical performance. Although grinding reduced the particle size of carbon black, it also decreased its structural integrity. When carbon black is well dispersed within the rubber matrix and retains sufficient structural characteristics, the reinforcing effect is more pronounced. Consequently, the wet flocculation process using sieved filtration N110 carbon black produced the best physical and mechanical properties among the tested samples.

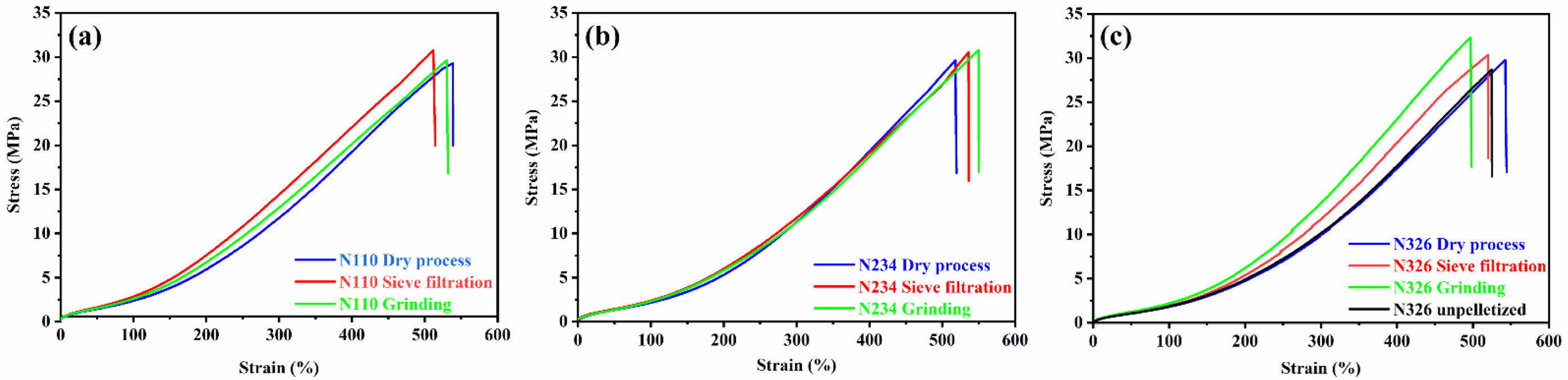

Figure 3 presents the stress–strain curves of rubber composites reinforced with N110 (Figure 3(a)), N234 (Figure 3(b)), and N326 (Figure 3(c)) carbon blacks, respectively. In the initial stage of tensile testing, the rubber composites exhibited an approximately linear relationship between stress and strain.26

The particle size of N234 carbon black was not significantly different from that of N326; however, its DBP structure value was approximately 125, higher than both N326 and N110. Grinding carbon black and the sieve filtration carbon black wet process had basically the same physical and mechanical properties, both of which were improved compared with the dry process, with the tensile strength and M300%/M100% improved by 3.74% and 4.85%, respectively, compared with the corresponding dry process. This enhancement can be explained by the reduction in particle size and structure due to grinding: a decrease in particle size generally enhances dispersion in the rubber matrix, whereas a decrease in structure tends to weaken reinforcement. In contrast, the sieving filtration N234 carbon black maintained its original particle size, but the removal of structurally inferior fractions during sieving led to an overall quality improvement. As a result, the differences in performance between the two wet mixing approaches were minimal.27

As shown in Figure 3(c), the grinding process demonstrated superior performance. The tensile strength and the M300%/M100% modulus ratio were higher than those of the other processes, with increases of 11.21% and 14.62%, respectively, compared with the dry mixing process. This improvement was attributed to the enhanced reinforcing efficiency of the grinding carbon black. Although both particle size and structural degree were reduced by the grinding process, the reduction in particle size had a more significant effect, improving dispersion and overall reinforcement within the rubber matrix. Furthermore, in the case of sieving filtration carbon black, where both particle size and structure remained largely unchanged, the wet mixing process still exhibited improved tensile strength, reinforcement coefficient (M300%/M100%), and constant tensile stress compared to the corresponding dry mixing process. This suggests that even without changes in morphology, the wet mixing approach enhances dispersion and filler–matrix interaction, contributing to improved mechanical properties.

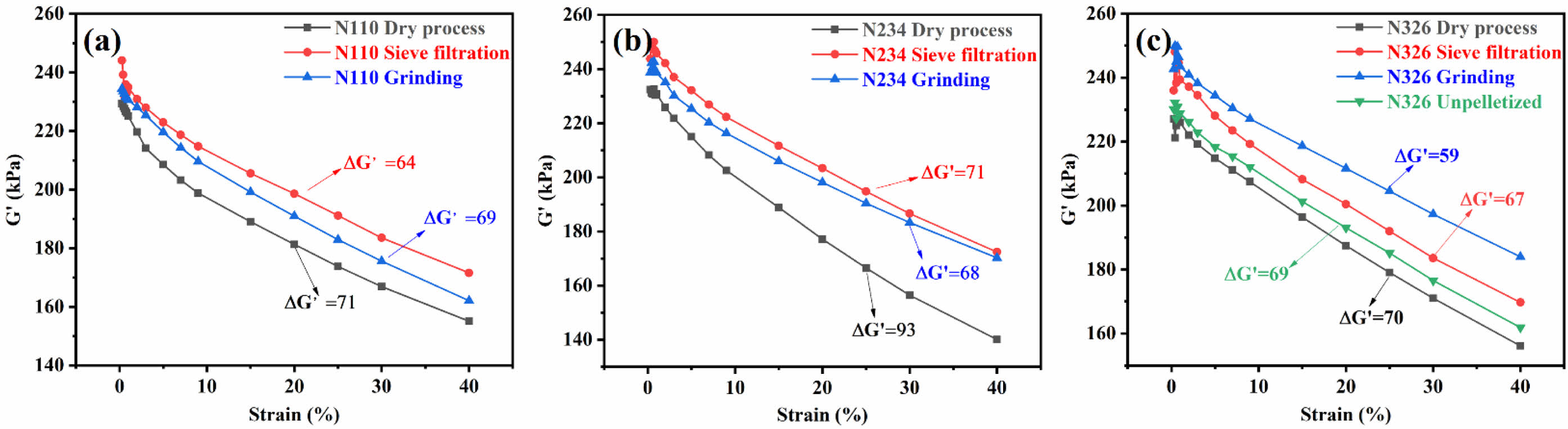

Payne Effect. As strain increased, the storage modulus gradually decreased, a phenomenon known as the Payne effect, which characterizes the filler–filler network structure in composite blends. A larger difference in storage modulus (ΔG′) indicates a stronger filler network, more severe carbon black agglomeration, and poorer dispersion.28

As shown in Figure 4(a), for N110 carbon black, the magnitude of the Payne effect followed the order: N110 dry process > N110 grinding > N110 sieving filtration. This trend can be explained by the inherently small particle size of N110 carbon black, which limited the particle size reduction achieved through grinding. Additionally, grinding hindered dispersion in the wet process. In contrast, sieving filtration carbon black benefited from improved dispersion, leading to a lower ΔG′ and better filler distribution.

Figure 4(b) illustrates the Payne effect of N234 carbon black. The ΔG′ of the wet process was significantly lower than that of the dry process, with the ΔG′ value of the wet sieving filtration carbon black being 23.66% lower than that of the dry process. This improvement is attributed to the enhanced dispersion capability of the wet mixing method. The combined effects of better dispersion and partial removal of poorly performing carbon black particles—without a significant reduction in particle size—resulted in an overall Payne effect similar to that of grinding carbon black.

Figure 4(c) presents the Payne effect for N326 carbon black. The ΔG′ values followed the order: N326 dry process > N326 powdered > N326 sieving filtration > N326 grinding, indicating that the wet-processed, grinding carbon black exhibited the weakest Payne effect. This suggests the highest degree of dispersion was achieved in this condition. In contrast, the sieving filtration carbon black displayed a higher ΔG′ due to a broader particle size distribution and less uniform dispersion. The powdered carbon black, due to its low bulk density and poor flowability, also showed a strong Payne effect as a result of inadequate dispersion in the viscous rubber matrix.

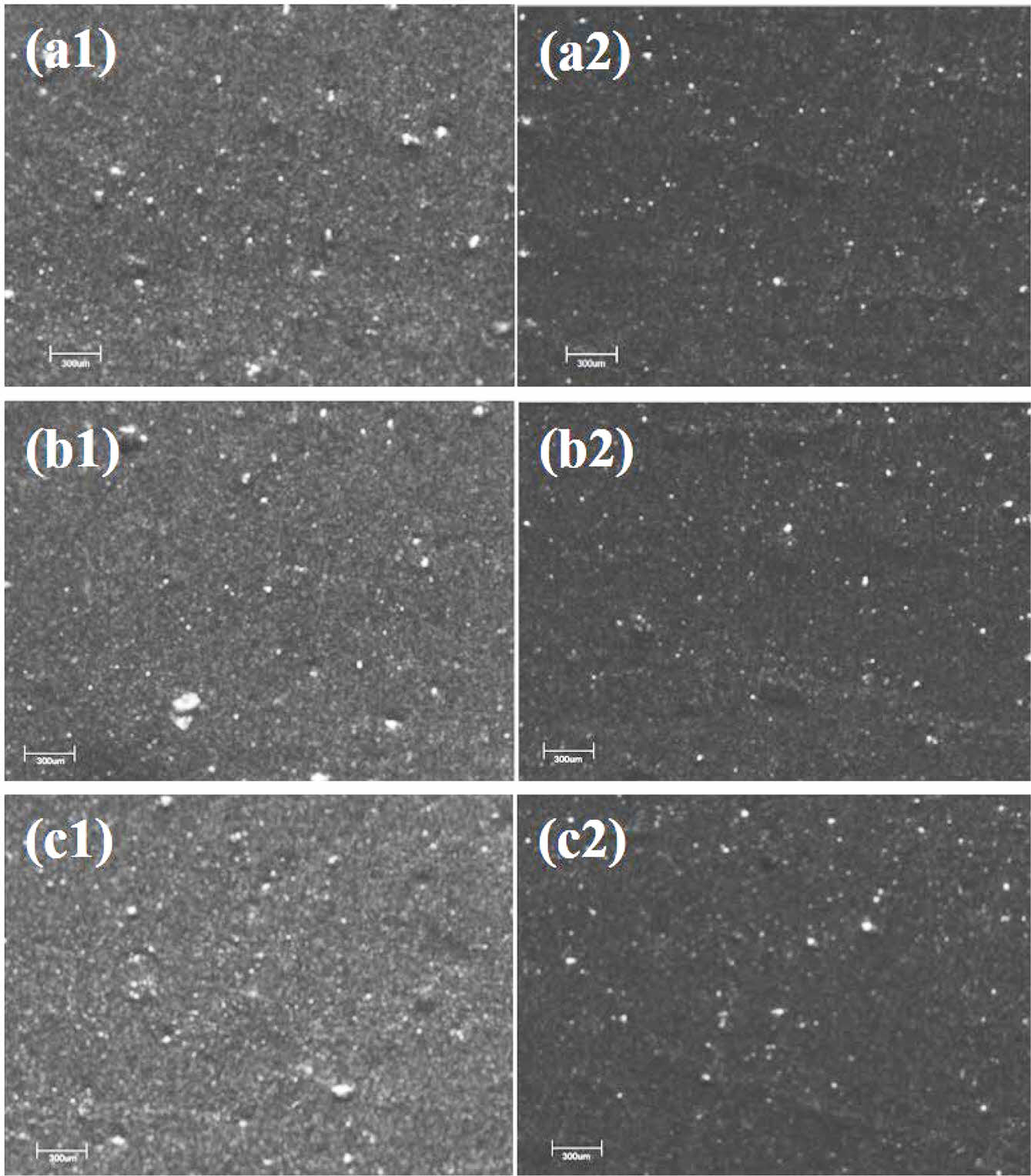

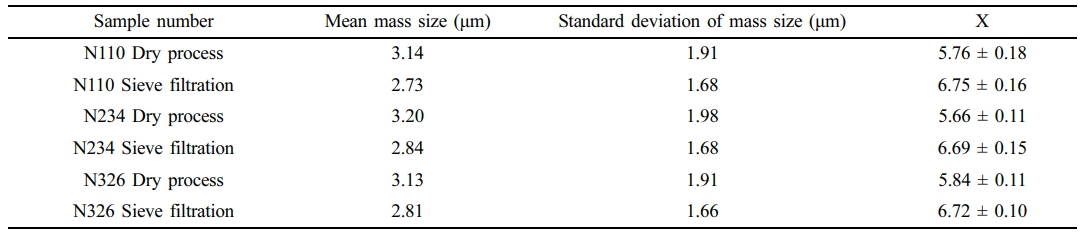

Carbon Black Dispersion. The dispersion of carbon black within the rubber matrix is directly related to the overall properties of the rubber compound. A carbon black dispersion analyzer was used to evaluate the size, morphology, and distribution of carbon black particles, followed by particle size analysis and image comparison to determine the dispersion grade. The parameter X represents the uniformity of carbon black aggregate dispersion in the rubber, with a higher X value indicating better dispersion.

According to the data presented in Table 4, the agglomerated particle size in rubber prepared via the wet mixing process was generally smaller than that of the corresponding dry process. This finding demonstrates that the wet mixing method provides improved dispersion of carbon black within the rubber matrix.29

As shown in Figure 5, the white bright spots in the image represent the reflected light from carbon black particles. The dispersion of carbon black in the wet mixing process was generally superior to that of the dry mixing process. This improvement could be attributed to the fact that the particle size of the sieving filtration carbon black was close to the dispersion threshold required by the wet flocculation process. Under rapid stirring and flocculation conditions, no significant carbon black agglomeration occurred, and more contact points were formed between carbon black particles and rubber molecular chains.30

The rubber chains exhibited a strong affinity for carbon black, which further reduced agglomeration and enhanced the reinforcing effect. Therefore, the structural characteristics of carbon black are primarily determined by particle size and specific surface area. When combined with the wet mixing method, these properties contribute to enhanced dispersion and improved mechanical performance of the rubber composite.31

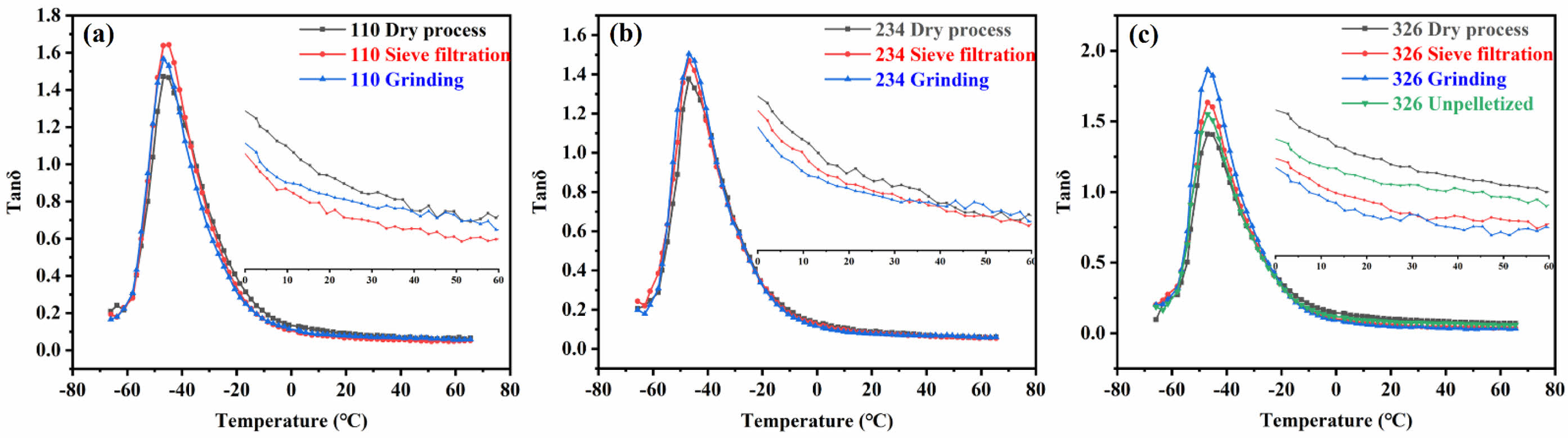

Dynamic Mechanical Properties. As shown in Figure 6, the relationship between the loss factor (tan δ) and temperature for vulcanizates prepared using the wet process for three different grades of powdered carbon black, as well as those prepared by the corresponding dry processes, is presented. It can be observed that the loss peaks of vulcanizates from all processes occurred at the same temperature, indicating identical glass transition temperatures (Tg). The peak value of tan δ in the glass transition region reflects the mobility state of the rubber molecular chains. The energy dissipation in this region primarily arises from internal friction between molecular chains. Since the rubber chains in the wet process did not experience prolonged thermal aging or chain scission, they retained more flexible segments, leading to increased intermolecular friction and consequently a higher tan δ peak. Moreover, the peak of tan δ in the glass transition region is also influenced by the degree of filler dispersion. A higher level of filler dispersion reduces the restriction on molecular chain mobility, enhances molecular friction, and thereby increases the peak value of tan δ.

As shown in Figure 6(a), the sieving filtration N110 carbon black prepared via the wet process exhibited the highest peak tan δ value, indicating the best carbon black dispersion among the samples. At 60 ℃, the wet-process vulcanizate demonstrated a lower tan δ value compared to its dry-process counterpart, suggesting that the wet process resulted in lower rolling resistance. Conversely, at 0 ℃, the dry-process sample exhibited a higher tan δ value than the wet-process sample, implying superior wet skid resistance. Among the samples, the vulcanizate prepared using sieving filtration carbon black in the wet process showed the lowest rolling resistance. These results indicated that the wet process enhances the rolling resistance performance of vulcanized rubber but may compromise its wet skid resistance.

From Figure 6(b), it would be observed that in the glass transition region, the peak tan δ value of the wet-process sample was higher than that of the dry-process sample, while the glass transition temperatures remained essentially the same. This indicates that carbon black dispersion in the wet process was superior to that in the dry process, and that the two wet-process methods exhibited comparable levels of dispersion. The underlying reason, based on analysis, is that the particle size and structural characteristics of N234 carbon black resulted in similar dispersion effects for both powdered carbon black preparation methods. The tan δ values at 0 ℃ and 60 ℃ are related to the wet skid resistance and rolling resistance, respectively. Compared to the dry process, the wet process slightly improved the rolling resistance performance but slightly reduced the wet skid resistance.

From Figure 6(c), it can be observed that the glass transition temperatures of the dry process and each wet process remained nearly unchanged. In terms of the peak tan δ, the dry-process sample exhibited the lowest peak, while the carbon black grinding wet-process sample showed the highest. The reason for this is that the dispersion of carbon black in the N326 grinding wet process resulted in a weaker filler–filler network and less carbon black agglomeration, thereby leading to a higher energy dissipation peak. The figure also reflects the anti-slip and rolling resistance performance of the vulcanized rubber. The dry process exhibited better wet skid resistance but higher rolling resistance. Among all samples, the grinding wet-process sample had the lowest rolling resistance and lower heat build-up.

|

Figure 2 Physical mechanical properties of different powdered carbon black and mixing methods: (a) tensile stress at definite elongation and M300%/M100%; (b) tensile strength and elongation at break; (c) hardness (shore A). |

|

Figure 3 Stress–strain curves of carbon black reinforced rubber composites with different mixing methods: (a) N110/NR; (b) N234/NR; (c) N326/NR. |

|

Figure 4 Curves changes in storage modulus with strain of CB/NR composites prepared by different mixing methods: (a) N110/NR; (b) N234/NR; (c) N326/NR. |

|

Figure 5 Carbon black dispersion of CB/NR composites prepared by wet method and dry method: N110-Dry process (a1) and N110-Wet sieve filtration (a2), N234-Dry process (b1) and N234-Wet sieve filtration (b2), N326-Dry process (c1) and N326-Wet sieve filtration (c2). |

|

Figure 6 Dynamic mechanical properties of CB/NR composites prepared by wet method and dry method: (a) N110/NR; (b) N234/NR; (c) N326/NR. |

|

Table 2 Particle Size, Distribution, Structure and Specific Surface Area of Different Forms Carbon Black |

|

Table 3 Vulcanization Characteristics of CB/NR Compounds Prepared Using Different Carbon Black Treatment Methods and Mixing Processes |

In this study, carbon black masterbatches were prepared using the wet flocculation process. Various experimental approaches were investigated, including grinding and sieving filtration, for three grades of carbon black: N110, N234, and N326. The properties and flocculation behavior of the wet-process masterbatches prepared using different carbon black treatments were systematically analyzed. Compared with the dry process, the wet-process masterbatches exhibited enhanced performance.

The performance of carbon black masterbatch rubber prepared via the wet mixing process was significantly superior to that of the dry mixing process, particularly when the carbon black was subjected to sieving filtration treatment. For sieving filtration N110 carbon black, the MH–ML value was 8.4% higher, tensile strength increased by 3.65%, the Payne effect was reduced by 15.71%, and the tan δ value at 60 ℃ showed minimal change compared with the dry process. Sieving filtration N234 carbon black exhibited a 4.24% increase in MH–ML, a 3.44% increase in tensile strength, a 23.66% reduction in the Payne effect, and a comparable tan δ value at 60 ℃. For sieving filtration N326 carbon black, the MH–ML value increased by 7.1%, tensile strength improved by 11.21%, and the Payne effect decreased by 11.21%, with the tan δ value at 60 ℃ remaining nearly unchanged.

The dispersion of carbon black in the wet process was significantly better than that in the dry process, indicating that carbon black could be more uniformly distributed within the rubber matrix under wet mixing conditions. The flocculation time in the wet flocculation process varied depending on the pretreatment method of the carbon black. Pelletized carbon black subjected to grinding or sieving filtration was able to gel with natural latex within a short time under appropriate stirring conditions, whereas unprocessed pelletized carbon black required a longer time to achieve flocculation. Therefore, the wet masterbatch prepared through different experimental methods represents a flocculant-free flocculation approach, enabling acid-free flocculation and eliminating wastewater generation, at the same time, it saves energy and promotes the development of green, low-energy rubber processing.

- 1. Zhang, G. J.; Wang, G.; Jiang, Y.; Wang, S. F.; Zhang, Y. Preparation and Properties of Rice Husk Ash Silica Filled Natural Rubber. Polym. Composite 2024, 45, 438-447.

-

- 2. Zhai, X.; Chen, Y.; Han, D.; Zheng, J.; Wu, X.; Wang, Z.; Li, X.; Ye, X.; Zhang, L. New Designed Coupling Agents for Silica Used in Green Tires with Low VOCs and Low Rolling Resistance. Appl. Surf. Sci. 2021, 558, 149819.

-

- 3. Wisniewska, P.; Haponiuk, J. T.; Colom, X.; Saeb, M. R. Green Approaches in Rubber Recycling Technologies: Present Status and Future Perspective. ACS Sustainable Chem. Eng. 2023, 11, 8706-8726.

-

- 4. Hinchiranan, N.; Lertweerasirikun, W.; Poonsawad, W.; Rempel, G. L.; Prasassarakich, P. Cure Characteristics and Mechanical Properties of Hydrogenated Natural Rubber/Natural Rubber Blends. J. Appl. Polym. Sci. 2009, 111, 2813-2821.

-

- 5. Ruhida, A. R.; Hassan, A.; Shamheza, S. Effect of Filler on the Total Protein Content and Mechanical Properties of Natural Rubber Latex Films at Dif-ferent Filler Loadings. J. Rubber Res. 2020, 23, 217-225.

-

- 6. Nuinu, P.; Sirisinha, C.; Suchiva, K.; Daniel, P.; Phinyocheep, P. Improvement of Mechanical and Dynamic Properties of High Silica Filled Epoxide Functionalized Natural Rubber. J. Mater. Res. Technol. 2023, 24, 2155-2168.

-

- 7. Yantaboot, K.; Amornsakchai, T. Effect of Preparation Methods and Carbon Black Distribution on Mechanical Properties of Short Pineapple Leaf Fiber-carbon Black Reinforced Natural Rubber Hybrid Composites. Polym. Test. 2017, 61, 223-228.

-

- 8. Fang, Y.; Dong, H.; Hao, X.; Liu, Y.; Tang, D.; Zhao, H.; Zhou, W.; Sun, C.; Zhang, L. Enhanced Fatigue Resistance of Plasma Modified Pyrolysis Carbon Black Filled Natural Rubber Composites. Appl. Surf. Sci. 2024, 643, 158707.

-

- 9. Qiu, Y. W.; Zhang, A. Q.; Wang, L. S. Carbon Black-Filled Styrene Butadiene Rubber Masterbatch Based on Simple Mixing of Latex and Carbon Black Suspension: Preparation and Mechanical Properties. J. Macromol. Sci. B, 2015, 54, 1541-1553.

-

- 10. Luo, K. Y.; Wang, Z. F.; Yong, Z. F. Application of Wet Carbon Black Masterbatch in Green Mining Radial Tires. Polym. Eng. Sci. 2024, 64, 5784-5797.

-

- 11. Zhao, Q. H.; Niu, F. Y.; Liu, J. Y.; Yin, H. S. Research Progress of Natural Rubber Wet Mixing Technology. Polymers 2024, 16, 1899.

-

- 12. Wang, C.; Gong, Z.; Ge, Y.; Bian, H.; Xiao, Y. The Reinforcement of Deep Eutectic Solvents/silica/natural Rubber Wet Acid-free Masterbatch on Devil's Tri-angle Performance of Green Tires. Polym. Test. 2025, 143, 108700.

-

- 13. Wang, J.; Zhang, K. Y.; Cheng, Z. G.; Lavorgna, M.; Xia, H. S. Graphene/carbon Black/natural Rubber Composites Prepared by a Wet Compounding and Latex Mixing Process. Plast. Rubber Compos. 2018, 47, 398-412.

-

- 14. Xiao, W.; Yu, S. T.; Cao, X. J.; Su, K. Y.; Qu, Q. L.; Tan,Y. J.; Zhao, F.; Zhao, S.; Zhang, G. F.; Gao, A. L.; Cui, J.; Yan, Y. H. High-speed Shear Dispersion of MWCNTs Assisted by PVP in Water and Its Effective Combination with Wet-mixing Technology for NR/MWCNTs Nanocomposites. Polym. Composite 2022, 43, 3858-3870.

-

- 15. Wang, Y. Q.; Liao, L. S.; Zhong, J. P.; He, D. N.; Xu, K.; Yang, C. J.; Luo, Y. Y.; Peng, Z. The Behavior of Natural Rubber-epoxidized Natural Rubber-silica Composites Based on Wet Masterbatch Technique. J. Appl. Polym. Sci. 2016, 133, 43571.

-

- 16. Phumnok, E.; Khongprom, P.; Ratanawilai, S. Preparation of Natural Rubber Composites with High Silica Contents Using a Wet Mixing Process. ACS Omega 2022, 7, 8364-8376.

-

- 17. Xiao, Y.; Li, B.; Huang, Y.; Gong, Z.; Diao, P.; Wang, C.; Bian, H. High-value Application of Kaolin by Wet Mixing Method in Low Heat Generation and High Wear-resistant Natural Rubber Composites. Appl. Clay Sci. 2024, 261, 107574.

-

- 18. Xiao, Y.; Huang, Y. G.; Li, B.; Ge, Y. Q.; Gong, Z.; Xu, Z. C.; Wang, C. S.; Bian, H. G.Preparation of Oil Resistant and High-temperature Resistant NBR Composites by Modified Graphene Oxide/silica/coupling Agent-flocculation Process. J. Polym. Res. 2025, 32, 20.

-

- 19. Yusof, N. H.; Som, F. M.; Said, M. M. Preparation of Silica-ENR Masterbatch via Latex Stage. J. Rubber Res. 2011, 14, 185-199.

- 20. Yang, J.; Xian, B.; Li, H.; Zhang, L.; Han, D. Preparation of Silica/natural Rubber Masterbatch Using Solution Compounding. Polymer 2022, 244, 124661.

-

- 21. Bian, H. G.; Xue, J. X.; Hao, G. Q.; Hao, Y. J.; Xie, M.; Wang, C. S.; Wang, Z. F.; Zhu, L.; Xiao, Y. High Thermal Conductivity Graphene Oxide/carbon Nanotubes/butyl Rubber Composites Prepared by a Dry Ice Expansion Pre-dispersion Flocculation Method. J. Appl. Polym. Sci. 2022, 139, e51897.

-

- 22. He, X.; Z. Peng, N. Yu, J. Han and C. Wu, Poly(sodium 4-styrenesulfonate) Modified Carbon Nanoparticles by a Thermo-mechanical Technique and Its Reinforcement in Natural Rubber Latex. Compos. Sci. Technol. 2008, 68, 3027-3032.

-

- 23. Wang, M. J.; Wang, T.; Wong, Y. L.; Shell, J.; Mahmud, K. J. K. U. G. K. NR/carbon Black Masterbatch Produced with Continuous Liquid Phase Mixin G. Kautschuk Gummi Kunststoffe 2001, 55, 388-396.

- 24. Tian, X.; Zhuang, Q.; Han, S.; Li, S.; Liu, H.; Li, L.; Zhang, J.; Wang, C.; Bian, H. A Novel Approach of Reapplication of Carbon Black Recovered From Waste Tyre Pyrolysis to Rubber Compo-sites. J. Clean. Prod. 2021, 280, 124460.

-

- 25. Yasir, H. A.; Al-Maamori, M. H.; Ali, H. M. Effect of Carbon Black Types on Curing Behavior of Natural Rubber. Europ. J. Adv. Eng. Technol. 2015, 2, 77-80.

- 26. Chollakup, R.; Suethao, S.; Suwanruji, P.; Boonyarit, J.; Smitthipong, W. Mechanical Properties and Dissipation Energy of Carbon Black/rubber Composites. Compos. Adv. Mater. 2021, 30, DOI: 10.1177/26349833211005476.

-

- 27. Le, H. H.; Ilisch, S.; Radusch, H. J. Characterization of the Effect of the Filler Dispersion on the Stress Relaxation Behavior of Carbon Black Filled Rubber Composites. Polymer 2009, 50, 2294-2303.

-

- 28. Gan, S.; Wu, Z. L.; Xu, H.; Song, Y.; Zheng, Q. Viscoelastic Behaviors of Carbon Black Gel Extracted from Highly Filled Natural Rubber Compounds: Insights into the Payne Effect. Macromolecules 2016, 49, 1454-1463.

-

- 29. Han, J.; Zhang, Y.; Wu, C.; Ma, Y. J. P. C. Effect of Reynolds Number on the Dispersion of Carbon Black in Natural Rubber Latex and Filler-rubber Interfacial Interaction in High-speed Jet Flow Field. Polym. Compoites 2013, 34, 1071-1075.

-

- 30. Tomita, Y.; Lu, W.; Naito, M.; Furutani, Y. Numerical Evaluation of Micro- to Macroscopic Mechanical Behavior of Carbon-black-filled Rubber. International J. Mech. Sci. 2006, 48, 108-116.

-

- 31. Huang, L. H.; Yang, X. X.; Gao, J. H. Study on Microstructure Effect of Carbon Black Particles in Filled Rubber Composites. Int. J. Polym. Sci. 2018, 2018, 2713291.

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2024 Impact Factor : 0.6

- Indexed in SCIE

This Article

This Article

-

2025; 49(6): 799-809

Published online Nov 25, 2025

- 10.7317/pk.2025.49.6.799

- Received on Jun 9, 2025

- Revised on Jul 3, 2025

- Accepted on Jul 31, 2025

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

- Conflict of Interest

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Chuansheng Wang

-

*College of Electromechanical Engineering, Qingdao University of Science & Technology, Qingdao 266061, China

**National Engineering Laboratory of Advanced Tire Equipment and Key Materials, Qingdao University of Science & Technology, Qingdao 266061, China - E-mail: wcsmta@qust.edu.cn

- ORCID:

0009-0003-9943-8247

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.