- Gloss Control of PMMA/ABS Co-extrusion Sheet Using Cross-linked PMMA Particles

Sang-In Lee*, **

, Hae-chan Cheong**, Jung-Woon Park**, Minji Kim*, and Hyun-jong Paik*,†

, Hae-chan Cheong**, Jung-Woon Park**, Minji Kim*, and Hyun-jong Paik*,†

*Department of Polymer Science and Engineering, Pusan National University, Busandaehak-ro 63beon-gil, Geumjeong-gu, Busan 46241, Korea

**LX MMA R&D Center, 188, Munji-ro, Yuseong-gu, Daejeon 34122, Korea- 가교 PMMA 입자를 이용한 PMMA/ABS 공압출 시트 광택 조절

*부산대학교 고분자공학과, **LX MMA 기술연구소

Reproduction, stored in a retrieval system, or transmitted in any form of any part of this publication is permitted only by written permission from the Polymer Society of Korea.

For investigating the gloss control of poly(methyl methacrylate) (PMMA)/poly(acrylonitrile-co-butadiene-co-styrene) (ABS) co-extrusion sheet by cross-linked PMMA particles, six PMMA mixture samples were prepared through an extrusion process using cross-linked PMMA particles with two different sizes (13.2 and 17.4 μm) in three different contents (20, 22.5, and 25 wt%). PMMA/ABS co-extrusion sheets (3 mm) were manufactured using PMMA compounding mixtures and white ABS; the thickness of the upper PMMA layer was about 100 um. The PMMA/ABS co-extrusion sheets had super matte surface with low gloss (less than 7 GU, measuring angle 60°). We investigated the effects of size and contents of cross-linked PMMA particles on the gloss and roughness of the surface of super matte PMMA/ABS co-extrusion sheet by using a confocal laser scanning microscope (CLSM), contact roughness tester and surface glossmeter.

폴리메틸메타크릴레이트(PMMA) 가교 입자를 이용하여 PMMA 컴퍼지트 제품 표면의 광택을 조절하는 실험을 진행하였다. 단분산 입도를 가지는 2개의 다른 사이즈(13.2, 17.4 μm)의 가교된 PMMA 입자를 3가지 조성(20, 22.5, 25 wt%)으로 압출 컴파운딩 공정을 통해 PMMA 혼합물 샘플을 제작하였다. 컴파운딩된 PMMA 혼합물을 화이트 불투명 아크릴로나이트릴·뷰타다이엔·스타이렌 수지(ABS)와 함께, 상층 PMMA 층의 두께는 약 100 μm이며 전체 공압출 시트의 두께는 3 mm인 6종의 PMMA/ABS 공압출 시트를 제작하였다. 이렇게 제작된 PMMA/ABS 공압출 시트는 초저광택(7GU 이하, 측정각 60°)을 가지는 슈퍼매트 표면이 구현되었으며, 본 연구에서는 공초점 레이저 주사 현미경(CLSM)과 접촉 거칠기 시험기 및 광택 측정기를 사용하여 가교 PMMA 입자의 크기와 함량에 따른 PMMA/ABS 공압출 시트 표면의 거칠기와 광택 변화를 조사하였다.

The surface roughness and gloss of super matte poly(methyl methacrylate) (PMMA)/poly(acrylonitrile-co-butadiene-co-styrene) (ABS) co-extrusion sheets with high cross-linked PMMA particle content were studied. Both the size and content of the cross-linked PMMA particles can affect the gloss of the PMMA/ABS co-extrusion sheet. Due to the high content of particles, super matte extruded surfaces can be obtained even with different roughness depending on the particle size.

Keywords: super matte poly(methyl methacrylate), cross-linked poly(methyl methacrylate), poly(methyl methacrylate)/poly(acrylonitrile-co-butadiene-co-styrene) co-extrusion sheet, gloss, surface roughness.

This work was supported by a 2-Year Research Grant of Pusan National University.

The authors declare that there is no conflict of interest.

Gloss is a very important appearance property that describes surface properties in many applications such as paints and plastics in electronics, home interiors and automotive industries. From a physical point of view, gloss is used to quantify the optical properties of a surface, which refers to how well it reflects light in the direction of specular reflection. Usually, this gloss is highly related to surface roughness. This is because in most cases the bulk contribution is small compared to what comes from the surface.1-9

In the case of plastic composite materials containing fillers, studies on the gloss according to the shape, size, and content of fillers have been conducted for a long time.10-14 The size distribution and shape of filler, differences in refractive index between filler and the matrix, and process variables such as injection speed, and mold temperature can influence the surface properties of the sample and its gloss.15,16 In the case of acrylic coatings, it has been reported that the gloss decreases as the content of inorganic fillers increases. Further, changes in gloss and surface roughness have been reported depending on the type of filler such as fibers or granules for poly(methyl methacrylate) (PMMA) composite materials.9-14

Multi-layer sheet technology using acrylic material has been continuously applied to control the surface properties by introducing organic/inorganic fillers into PMMA materials in various applications. The upper PMMA layer can be easily applied to block UV rays in to the matrix for example poly(acrylonitrile-co-butadiene-co-styrene) (ABS), polycarbonate (PC), poly(vinyl chloride) (PVC) etc., and to give a controlled gloss on the surface, various color expressions, and improved scratch-resistant properties.

In particular, PMMA composites using acrylic particles are considered to be high-quality materials with an aesthetically beautiful and translucent appearance by minimizing the difference in refractive index between the incorporated acrylic filler and PMMA matrix while providing perfect weather resistance. Recently, low gloss and matt look designs have been applied in various industries using PMMA composite materials.14,17-19

Different varieties of matt PMMA products are commercially introduced using a number of techniques, such as an additional matting agent, special co-monomer and matt molding technology.14-19

In this study, the specimens are co-extruded sheets coated

with super matte PMMA mixtures on the opaque white ABS

matrix. There are relatively high amounts of cross-linked PMMA particles in super matte PMMA, so the topology of the surface super matte PMMA layer can be recognized as the most important factor for gloss rather than the interference effect between the surface layer and the matrix layer. Because the content of cross-linked PMMA particles is in a fairly high range, it is difficult to produce a uniform and clear surface by the injection process. So, we prepared PMMA/ABS co-extruded sheets under the same extrusion conditions as much as possible to avoid interference from the process conditions.

Because both gloss and roughness are important factors for explaining the correlation of their visual perception of a surface on products, the change in surface roughness according to the size and content of cross-linked particles is observed and the correlations between surface roughness and surface gloss was discussed in detail.

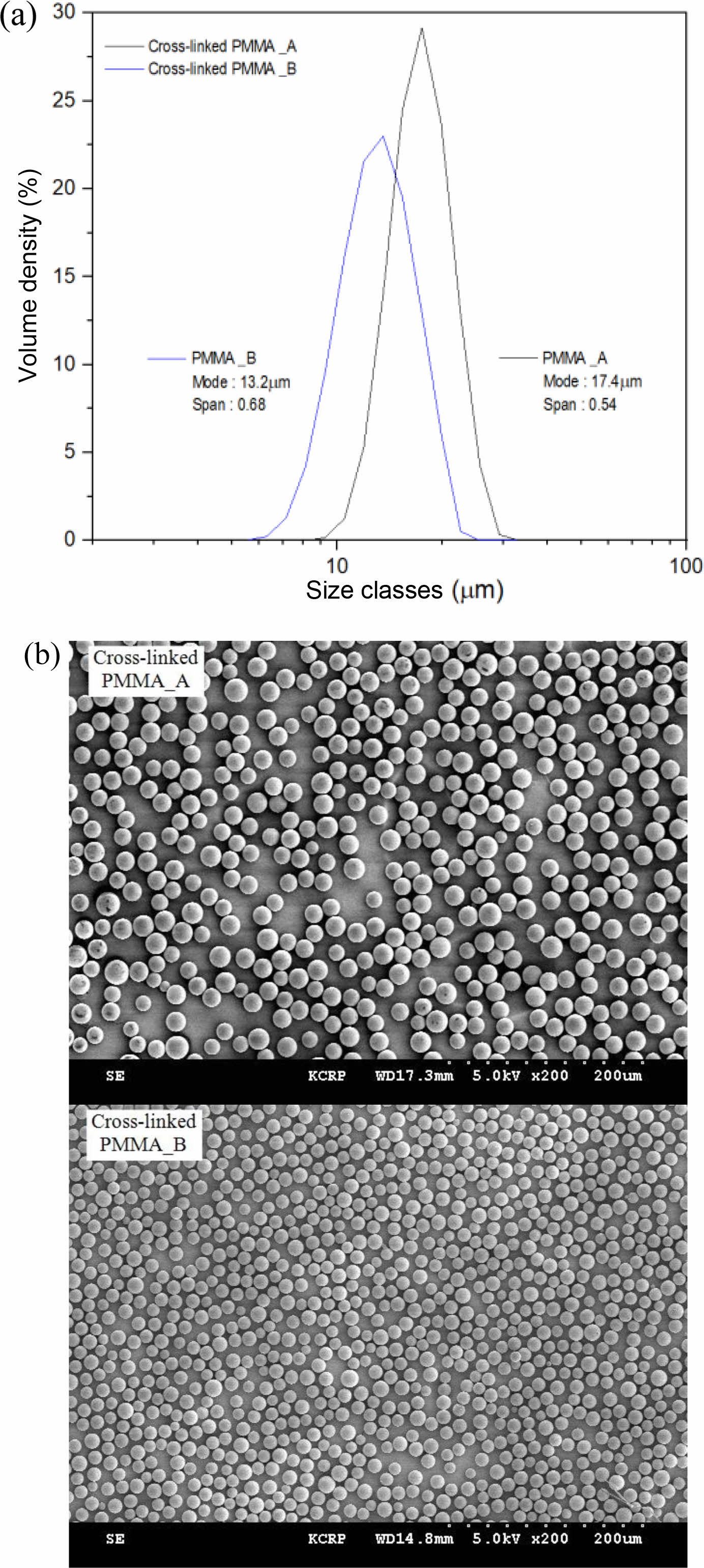

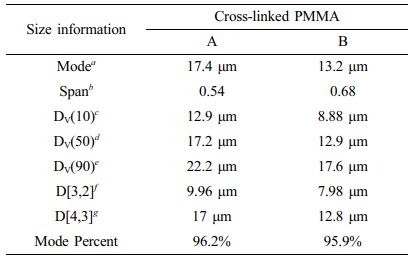

Material and Methods. Material: The cross-linked PMMA particles used supplied by LX MMA Co., Ltd. Figure 1 and Table 1 show the results of the characterization of cross-linked PMMA particles.

Characterization of Cross-linked PMMA Particles: Particle size, size distribution and morphology of the cross-linked PMMA particles were analyzed using a laser diffraction particle size analyzer Mastersizer3000 (Malvern) and a scanning electron microscope. Cross-linked PMMA A and B particles have narrow size distribution as shown in Figure 1. Detailed measured size information was listed in Table 1.

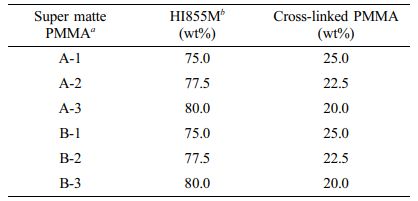

Super Matte PMMA/ABS Co-extrusion Sheet. Preparation of Super Matte PMMA Mixtures (Compounding Process): A series of super matte PMMA mixture samples were prepared through an extrusion compounding process using cross-linked PMMA particles of two different sizes (13.2 and 17.4 μm) with three different contents (20, 22.5, and 25 wt%) as listed in Table 2. Commercially available impact modified PMMA HI855M (LX MMA Co., LTD) was used as a thermoplastic matrix material. The cross-linked spherical PMMA particles were dried in a hot air oven before compounding into a thermoplastic matrix HI855M through S.M Platek TEK30® twin screw extruder equipped with a vacuum venting system. Screw diameter and L/D of TEK30® were 31.6 mm and 36 respectively. The more detailed extrusion conditions of the compounding process are as follows: Feed zone, 220 °C; compression zone, 240 °C; metering zone, 245 °C; die zone, 250 °C; and main screw RPM was 100.

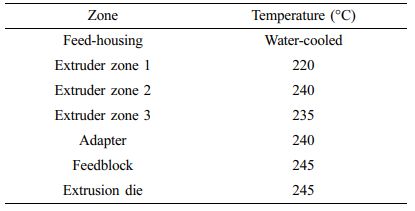

Co-extrusion Process for Super Matte PMMA/ABS: Six super matte PMMA mixtures were co-extruded with white color ABS RS650 (LG Chem. Co., LTD). For the series of super matte PMMA/ABS co-extrusion sheets, we used a multi-layer co-extrusion line (Omipa OM120, ITALY). The combination of the two melt streams (PMMA and ABS) within a fixed-flow-divider-type feed block is followed by shaping of the sheet geometry and cooling down through 3 calendar rolls. Co-extruded sheets were trimmed by a heated edge knife during the manufacturing process. We were able to produce co-extrusion sheets with a width of 300 mm and a thickness of 3 mm while the thickness of the upper layer was controlled at 100 μm. Table 3 shows detailed temperature settings of extruders, feedblock and extrusion die for co-extrusion.

|

Figure 1 (a) Size distribution; (b) SEM images of cross-linked PMMA particles A and B. |

|

Table 1 The Size Information for Cross-linked PMMA Particles (PMMA A and B) by Laser Diffraction Particle Size Analyzer |

aMode is the most commonly occurring size, also known as peak diameter. bSpan is an indication of the width of the distribution as follows: (DV(90) – DV(10))/DV(50). DV(10)c, DV(50)d, DV(90)e represent the maximum particle diameter in which 10, 50, and 90% of the sample volume exist, respectively. D[3,2]f is surface area moment diameter and D[4,3]g is volume moment mean diameter. |

|

Table 2 A Series of Super Matte PMMA Mixture |

aAll super matte PMMA samples were mixed with 0.1% antioxidant (Irganox1010, CIBA). bHI855M (LX MMA): 6.4 g/10 min (M.F.I, ISO1133 (230 °C, 3.8 kg)), 3.2 kJ/m2 (CHARPY Impact strength (notched), ISO179), 88 °C (VICAT Softening temperature, ISO 306(B/50)) |

Roughness and Gloss of Surface. For the accurate characterization of a surface, the surface roughness and gloss of six types of co-extrusion sheets were measured using a contact roughness tester (Surtronic S-116 Taylor Hobson) and portable glossmeter (Konica Minolta CM-25 Precise Gloss Meter).20,21 The average roughness in this research is based on the contact roughness method, which gives more significant values. The average roughness, Ra, is the value obtained by the following formula and is expressed in micrometers to define how much each point on the surface deviates in height from the average height. The roughness curve is expressed by y = f (x):1-5

The average roughness, Ra, was measured five times at different points in each specimen according to the ISO4287 method21 and the device precision was ±3% of the measured value per time and each evaluation length range was 4 mm.

Gloss is used to quantify the optical properties of a surface, which refers to how well it reflects light in the direction of specular reflection. As mentioned earlier, this gloss is highly related to surface roughness. The most well-known type of gloss from a shiny surface, the specular gloss is defined as:

where I is the intensity of specular reflection from the object, I0 is the specular reflectance from the standard specimen and θ is the angle of incident. For the micro rough surface with rms roughness amplitude σ, the specular intensity can be expressed by

with λ, the wavelength of the incident light and the angle of incident, θ.5,6 When the size of the surface irregularities is smaller than the wavelength, the proportion of mirror-reflected light relative to the diffuse light is large, and when the surface roughness is much larger than the wavelength, then the proportion of diffused reflected light is large. Several scientific studies have been carried out using the theory of light scattering on a rough Beckmann-Kirchhoff surface,7,8 then the expression of gloss from rough surface parameters should be highly complex.1-8

In our study, the surface gloss was compared with the 60° angle of incident light value by the ASTM D523 method.20 This is because the gloss values at an incident angle of 60 degrees are suitable to explain the gloss of a low gloss surface.1-5 Furthermore, we studied the surface scanning image of A- and B- super matte co-extrusion sheets by a high-speed confocal laser scanning microscope (CLSM) (NS-300, Nanoscope Systems). Measurements were carried out by moving three different points on the surface of the specimen cut into a size of 15 cm×15 cm.

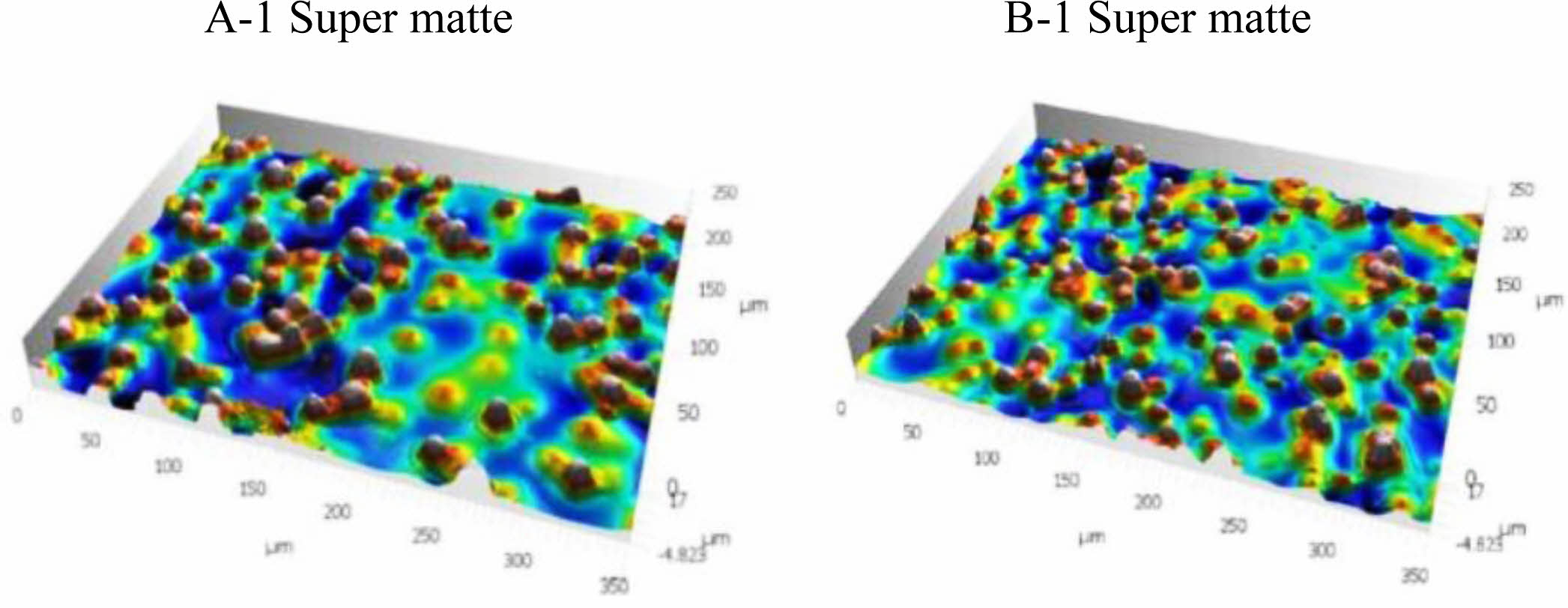

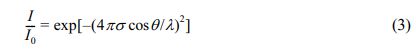

Surface Roughness and Gloss of Super Matte PMMA/ABS Co-extrusion Sheets. In Figure 2, the difference in particle size between the surface of the A- and B- series sheets could be distinguished. It is confirmed that the number of particles on the surface decreases with the decreasing contents of cross-linked PMMA particles (A1→A3, B1→B3).

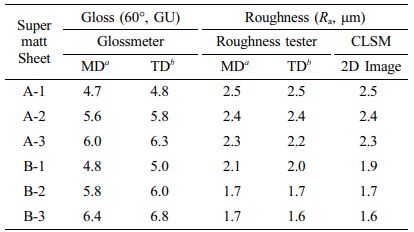

In Table 4, as expected, it was confirmed that there were differences in the surface roughness and gloss between A-series and B-series depending on the cross-linked PMMA particle size, and the difference was also confirmed according to the sheet processing direction. The sheet roughness of the A- series with larger particle size was larger than that of the B- series and the roughness in the longitudinal direction was consistently observed to be slightly larger than that in the transverse direction. Interestingly, it can be seen that the surface roughness values measured by the roughness tester and CLSM agree well with each other.

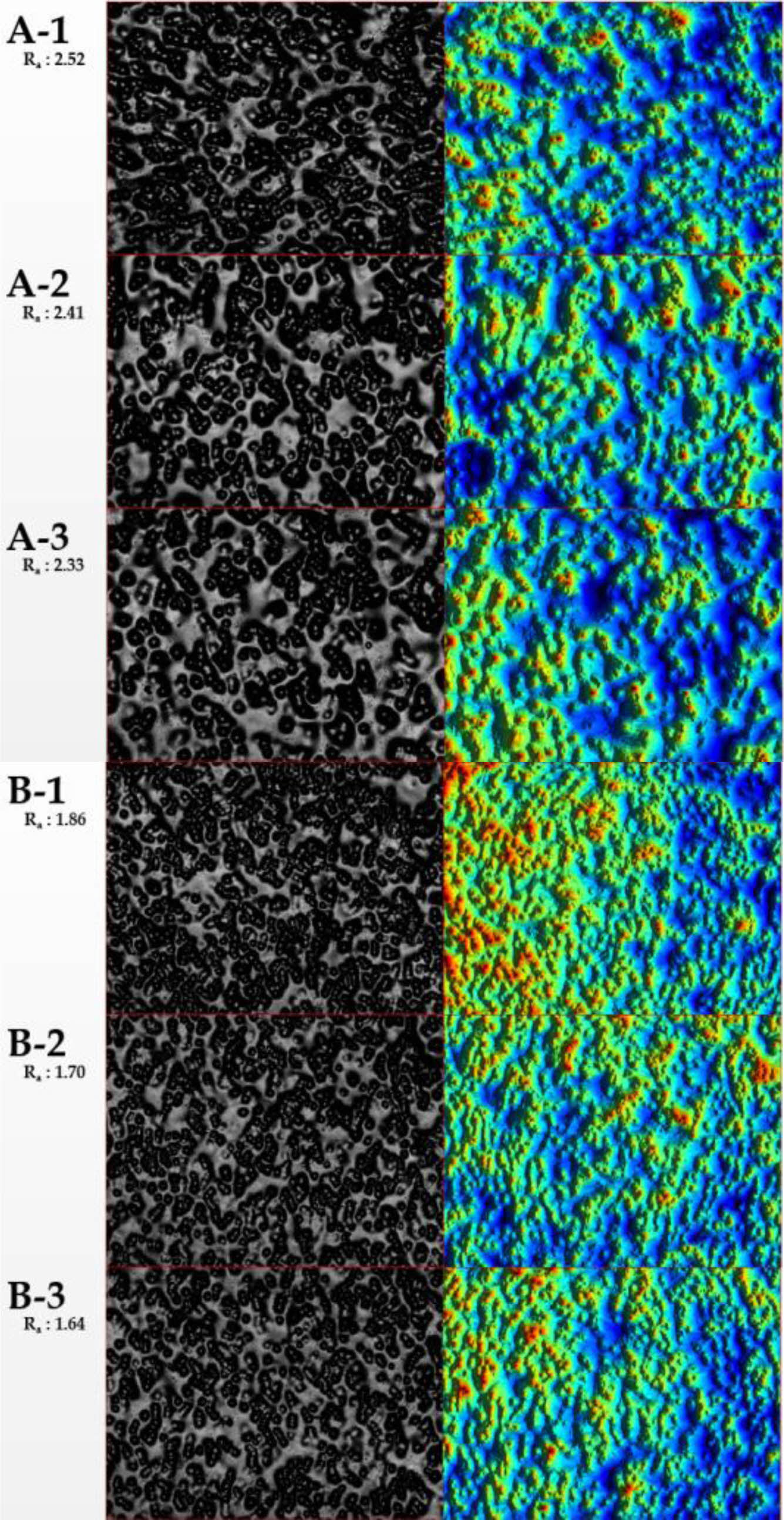

Figure 3(a) shows that with the increment of the amount of cross-linked PMMA particles in super matte PMMA, there is a higher degree of surface roughness of super matte PMMA/ABS co-extrusion sheets. Furthermore, it can be seen that the surface roughness of the A-series sheet with the larger particle size is slightly higher compared to the B-series. Figure 3(b) shows that with the increment of the amount of cross-linked PMMA particles, there is a decrease in the surface gloss. The gloss on the surface of the A-series sheet was slightly lower than the B-series.

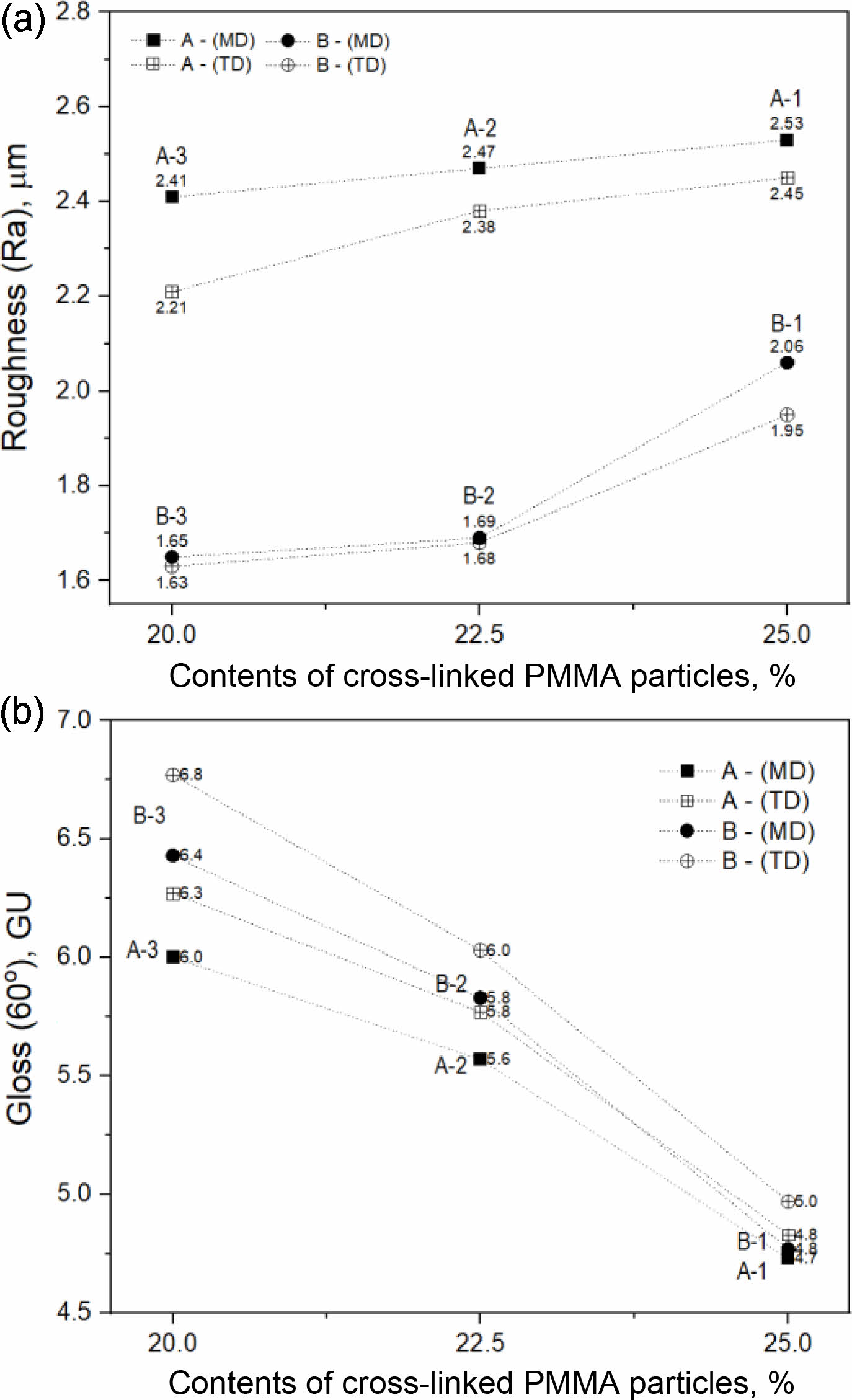

In Figure 3(a), it is of interest to note that the roughness in the longitudinal direction was consistently observed to be slightly larger than that in the transverse direction, and it is confirmed that a consistently lower gloss in the longitudinal direction was observed accordingly in Figure 3(b). Differences in surface roughness and gloss according to the processing direction had also been reported in previous research papers.22,23 The surface of the melt sheet passing through the extrusion die had continuously pressed between rolls; thus, the roughness in the transverse direction resulted in a slightly smoother surface than that in the longitudinal direction. Figure 4 shows the difference in roughness between the A-series and B-series. The difference in roughness is due to the different sizes of the cross-linked PMMA particles in super matte PMMA. In addition, both A-series and B-series showed an increase in roughness and a decrease in gloss as the content of cross-linked PMMA particles increased. Although there is a clear difference in the surface roughness values of A-1 and B-1, both the sheets achieved a similar low gloss surface (<5GU).

In Figure 4, it is interesting to note that the surface roughness of the A-3 sheet was higher than that of the B-1 sheet, while the surface gloss of the B-1 sheet was lower than the A-3 sheet. The higher gloss of the A-3 sheet having a rougher surface than the B-1 sheet confirms that the surface gloss is not solely dependent on the surface roughness. Both A-1 and B-1 super matte PMMA used the same weight ratio, 25 wt%, of crosslinked PMMA particles. As shown in Table 1, when the particle size of PMMA A is about 1.3 times larger than that of PMMA B based on both values of mode and median, there should be a larger number of particles in the B-1 sheet, and in simple calculations, there can be as much as (17.4 μm/13.2 μm)3 ratio, that is, 2.3 times of PMMA particles can exist in B-1 sheet. When we compared the number of particles between A-1 and B-1 images in Figure 2 after converting the A-1 and B-1 confocal surface scanning images using the graphic design program ImageJ, it was confirmed that there were 475 particles in A-1 and 780 particles in B-1. In the SEM image of Figure 4, a much larger number of cross-linked particles exists on the surface of the B-1 sheet. It implies that the more the cross-linked PMMA particles exist on the surface, the more effective the super matte surface is realized by increasing the light scattering efficiency of the surface along with the effect of surface roughness.

|

Figure 2 Surface image by confocal laser scanning microscopy (CLSM) for A-1, A-2, A-3, B-1, B-2, and B-3 co-extrusion sheets (image size: 700 μm×520 μm, magnification: ×100). |

|

Figure 3 The roughness and gloss of super matte PMMA/ABS coextrusion sheet as a function of contents of cross-linked PMMA particles in super matte PMMA: (a) roughness (Ra); (b) gloss (60°, GU). |

|

Figure 4 (a) Gloss as a function of surface roughness; (b) SEM images of A-1, B-1 super matte sheets. |

|

Table 4 The Roughness (Ra) and Gloss (60°, GU) Values of Super Matte PMMA/ABS Co-extrusion Sheet |

aMD (Material direction): longitudinal (rolling) direction of extruded sheet, bTD (Tangential direction): long transverse direction of extruded sheet |

In our experiment, the surface of super matte PMMA/ABS co-extrusion sheet was studied by measuring the gloss and roughness. As expected there were differences in the surface roughness and gloss of A-series and B-series depending on the cross-linked PMMA particle size. Although, there was a difference in surface roughness between the A-1 and B-1 series, they showed a similar level of low gloss. Hence, it can be suggested to use small-size matt agents with a high content such as B-1 to target low gloss on a smooth surface.

Additionally, it was confirmed that the correlation of gloss was not decided by the roughness effect alone while comparing A-3 with B-1. Despite the roughness of the A-3 sheet being higher than the B-1 sheet, the surface gloss of the B-1 sheet was lower than the A-3 sheet. This was due to a higher presence of cross-linked particles on the surface PMMA layer with increased light scattering efficiency. Thus, a more effective super matte surface can be realized by increasing the light scattering efficiency while controlling the surface roughness.

- 1. Chadwick, A. C.; Kentridge, R. The Perception of Gloss: A Review. Vision Res. 2015, 109, 221-235.

-

- 2. Alexander‐Katz, R.; Barrera, R. Surface Correlation Effects on Gloss. J. Polym. Sci. B: Polym. Phys. 1998, 36, 1321-1334.

-

- 3. Simonsen, I.; Larsen, Å. G.; Andreassen, E.; Ommundsen, E.; Nord‐Varhaug, K. Estimation of Gloss from Rough Surface Parameters. Phys. Status Solidi B Basic Res. 2005, 242, 2995-3000.

-

- 4. Elton, N. J.; Day, J. C. C. A Reflectometer for the Combined Measurement of Refractive Index, Microroughness, Macroroughness and Gloss of Low-extinction Surfaces. Meas. Sci. Technol. 2009, 20, 025309.

-

- 5. Yong, Q.; Chang, J.; Liu, Q.; Jiang, F.; Wei, D.; Li, H. Matt Polyurethane Coating: Correlation of Surface Roughness on Measurement Length and Gloss. Polymers 2020, 12, 326-338.

-

- 6. Elton, N. J. Optical Measurement of Microroughness of Pigment Coatings on Rough Substrates. Meas. Sci. Technol. 2008, 20, 025303.

-

- 7. Ragheb, H.; Hancock, E. Rough Surface Analysis using Kirchhoff Theory. Proceedings of the British Machine Conference, Norwich, GB, Sept 8-11, 2003.

-

- 8. Ragheb, H.; Hancock, E. R. The Modified Beckmann-Kirchhoff Scattering Theory for Rough Surface Analysis. Pattern Recognit. 2007, 40, 2004-2020.

-

- 9. Villalobos, R.; Chanona, J.; Hernández, P.; Gutiérrez, G.; Chiralt, A. Gloss and Transparency of Hydroxypropyl Methylcellulose Films Containing Surfactants as Affected by Their Microstructure. Food hydrocoll. 2005, 19, 53-61.

-

- 10. O'Brien, W. J.; Johnston, W. M.; Fanian, F.; Lambert, S. The Surface Roughness and Gloss of Composites. J. Dent. Res. 1984, 63, 685-688.

-

- 11. Campbell, P. M; Johnston, W. M.; O'brien, W. J. Light Scattering and Gloss of an Experimental Quartz-filled Composite. J. Dent. Res. 1986, 65, 892-894.

-

- 12. Dashtizadeh, A.; Abdouss, M.; Mahdavi, H.; Khorassani, M. Acrylic Coatings Exhibiting Improved Hardness, Solvent Resistance and Glossiness by Using Silica Nano-composites. Appl. Surf. Sci. 2011, 257, 2118-2125.

-

- 13. Ou, J.; Zhang, M.; Liu, H.; Zhang, L.; Pang, H. Matting Films Prepared from Waterborne Acrylic/micro‐SiO2 Blends. J. Appl. Polym. Sci. 2015, 132, 41707.

-

- 14. Wang, T.; Sun, Z.; Liang, F.; Fan, H.; Xiang, J.; Chen, Y. Poly(methylmethacrylate) Microspheres with Matting Characteristic Prepared by Dispersion Polymerization. Int. J. Polym. Anal. Charact. 2019, 24, 731-740.

-

- 15. Méndez, E. R.; Barrera, R. G.; Alexander-Katz, R. Light Scattering by Injection Molded Particle Filled Polymers. Phys. A: Stat. Mech. Appl. 1994, 207, 137-145.

-

- 16. Pisciotti, F.; Boldizar, A.; Rigdahl, M.; Arino, I. Effects of Injection‐molding Conditions on the Gloss and Color of Pigmented Polypropylene. Polym. Eng. Sci. 2005, 45, 1557-1567.

-

- 17. Zhang, X.; Cao, Y.; Jiang, Q.; Zhang, Y.; Yang, W. Preparation of Cross-linked Poly(methyl methacrylate) Microspheres Using an Asymmetric Cross-linker via Dispersion Polymerization and its Application in Light Diffusers. Colloid Polym. Sci. 2020, 298, 495-504.

-

- 18. Shen, S.; Sudol, E. D.; El‐Aasser, M. S. Control of Particle Size in Dispersion Polymerization of Methyl Methacrylate. J. Polym. Sci., Part A: Polym. Chem. 1993, 31, 1393-1402.

-

- 19. Shen, S.; Sudol, E. D.; El‐Aasser, M. S. Dispersion Polymerization of Methyl Methacrylate: Mechanism of Particle Formation. J. Polym. Sci., Part A: Polym. 1994, 32, 1087-1100.

-

- 20. ASTM D523-14. Standard Test Method for Specular Gloss. American Standards for Testing Materials. West Conshohocken, Pa, USA. 2018.

- 21. ISO 4287:1997, Geometrical Product Specifications (GPS) - Surface texture: Profile method - Terms, definitions and surface texture parameters, American National Standards Institute (ANSI), 2007.

-

- 22. Samyn, P.; Van Erps, J.; Thienpont, H. Specular Gloss Versus Surface Topography for Oil‐filled Nanoparticle Coatings on Paper. Color Res. Appl. 2016, 41, 596-610.

-

- 23. Oliveira, M.; Brito, A.; Costa, M.; Costa, M. Gloss and Surface Topography of ABS: A Study on the Influence of the Injection Molding Parameters. Polym. Eng. Sci. 2006, 46, 1394-1401.

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2022 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2023; 47(1): 72-78

Published online Jan 25, 2023

- 10.7317/pk.2023.47.1.72

- Received on Oct 19, 2022

- Revised on Nov 15, 2022

- Accepted on Nov 15, 2022

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

- Conflict of Interest

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Hyun-jong Paik

-

Department of Polymer Science and Engineering, Pusan National University, Busandaehak-ro 63beon-gil, Geumjeong-gu, Busan 46241, Korea

- E-mail: hpaik@pusan.ac.kr

- ORCID:

0000-0002-0821-9096

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.