- Influence of Stacking Sequence and Orientation on Tensile and Flexural Properties of Jute/glass/carbon Fiber Epoxy-based Hybrid Composites

Rajesh Kumar Dewangan, Samarjit Singh†

, Biplab Das, Manish Bhaskar, Pradeep Patanwar, Pankaj Kumar Gupta, Sung Soo Han*, and Rakesh Bhaskar*,†

, Biplab Das, Manish Bhaskar, Pradeep Patanwar, Pankaj Kumar Gupta, Sung Soo Han*, and Rakesh Bhaskar*,†

Department of Mechanical Engineering, School of Studies of Engineering & Technology, Guru Ghasidas Vishwavidyalaya, Bilaspur, Chhattisgarh-495009, India

*School of Chemical Engineering, Yeungnam University, Gyeongsan-38541, Korea- 황마/유리/탄소섬유 에폭시 기반 하이브리드 복합재료의 인장 및 굴곡 특성에 대한 적층 순서 및 배향의 영향

Rajesh Kumar Dewangan · Samarjit Singh†

· Biplab Das · Manish Bhaskar · Pradeep Patanwar · Pankaj Kumar Gupta · 한성수* · Rakesh Bhaskar*,†

· Biplab Das · Manish Bhaskar · Pradeep Patanwar · Pankaj Kumar Gupta · 한성수* · Rakesh Bhaskar*,†

Department of Mechanical Engineering, School of Studies of Engineering & Technology, Guru Ghasidas Vishwavidyalaya, Bilaspur

*영남대학교 화학공학부Reproduction, stored in a retrieval system, or transmitted in any form of any part of this publication is permitted only by written permission from the Polymer Society of Korea.

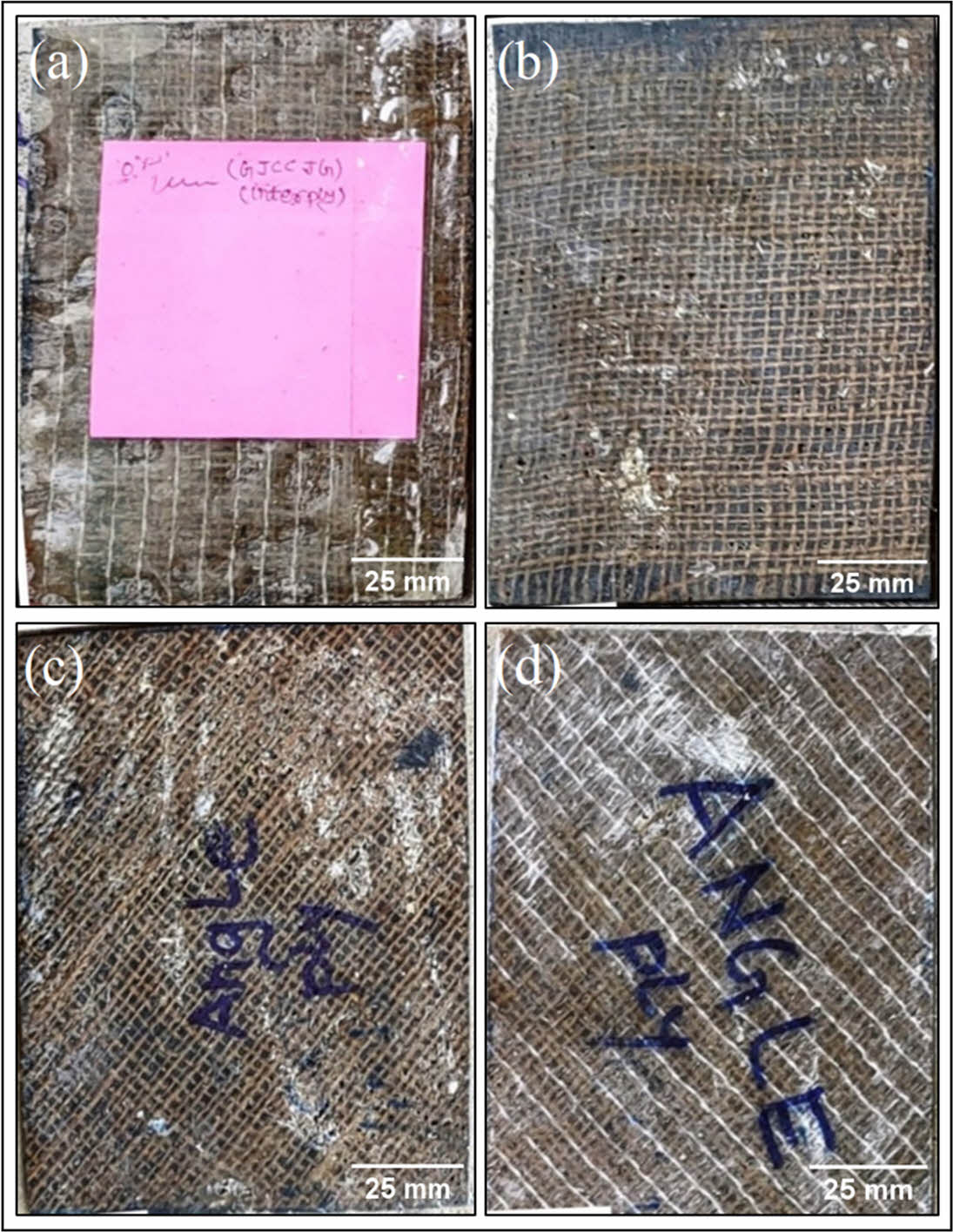

Natural fiber-reinforced epoxy composites have attracted the attention of researchers around the globe owing to their inherent noble attributes such as eco-friendly nature, lightweight, and low cost. However, these composites suffer from inferior mechanical properties and thus, continuous efforts are being made to improve the mechanical properties of these composites. The present work focuses on the tensile and flexural properties of jute (J)/glass (G)/carbon (C) fiber hybrid epoxy laminate composites in inter-ply and angle-ply configurations fabricated using the conventional hand lay-up technique. The impact of stacking sequence and orientation of fibers on the tensile and flexural behavior of epoxy laminate composite samples were evaluated. The results show that the hybrid arrangement of JCGs composite laminate has excellent tensile and flexural properties compared to the GJCs composite laminate at both 0° and 45°/-45° orientation of fiber layers. Therefore, it is possible to manufacture eco-friendly hybrid epoxy composites with encouraging mechanical properties.

천연섬유 강화 에폭시 복합재료는 친환경성, 생분해성, 경량성, 저렴한 가격과 같은 탁월한 특징으로 인해 연구자들의 주목을 받고 있으나 물성이 열악하여 기계적 물성을 개선하기 위한 노력이 계속되고 있다. 천연섬유와 합성섬유를 조합하여 하이브리드 에폭시 복합재료를 만들면 천연섬유 강화 에폭시 복합재의 기계적 물성을 크게 개선할 수 있다. 본 연구는 국제적으로 주목받는 황마(J)/유리(G), /탄소(C) 섬유 하이브리드 에폭시 라미네이트 복합재의 인터플라이 및 앵글플라이 배치에서의 인장 및 굴곡 특성에 초점을 두고 제작하여, 이러한 물성에 대한 섬유의 적층 순서와 방향성의 영향을 평가했다. 복합재의 배열순서의 효과를 보면, JCGs의 배열의 경우가 GJCs 배열의 경우 보다, 섬유층의 0° 및 45°/-45° 배향 모두에서, 우수한 인장 및 굴곡 특성을 가졌다. 또한, 인장 강도, 인장 탄성률, 굴곡 강도, 굴곡 탄성률, 강성 및 연성의 경우에도 유사한 결과를 나타내었다. 따라서, 비교적 약한 물성을 가지는 천연섬유를 포함한 복합재료 제조시, 동일한 재료의 조합이지만, 오직 배열의 순서만 바꾸어서, 보다 우수한 기계적 성질을 가지는 복합재료를 제조할 수 있어, 우수한 기계적 성질을 가지는 친환경 하이브리드 에폭시 복합재료의 개발이 가능할 것이다.

The present research work focuses on the tensile and flexural properties of jute (J)/glass (G)/carbon (C) fiber hybrid epoxy laminate composites in inter-ply and angle-ply configurations. The impact of stacking sequence and orientation of fibers on the tensile and flexural behavior of tested epoxy laminate composite samples were evaluated. The JCGs composite demonstrates good mechanical characteristics such as tensile strength, tensile modulus, flexural strength, flexural modulus, stiffness, and ductility at fabricated fiber orientation (0¡Æ & 45°/-45°).

Keywords: natural fibers, carbon fibers, glass fibers, mechanical property, epoxy-resin based hybrid composite, stacking sequence, fiber orientation.

The authors declare they have no competing interest or financial conflict among them.

The upliftment of the living standard of the human being is closely related to the development of customized materials. Nowadays, people’s interest has considerably increased in epoxy-based composite material because of its better mechanical properties like high tensile strength, lightweight, increased surface hardness, high impact resistance, higher insulating property, and reliability. Generally, natural fibers have lower strength and are easily degradable but when it is mixed with synthetic materials like epoxy, glass, and carbon fibers, the strength of the material becomes greater.1 Among the developed materials, composite materials are one of them. These materials are composed of the combination of two or more distinct components, made for obtaining properties that are different from the properties of the individual components.2 These materials possess properties that may not be found in traditional polymeric materials, ceramics, and metal alloys. The classification of the composite materials is done based on the usage of the matrix (i.e. polymeric, metallic, and ceramics) and usage of the reinforcement material used (i.e. fibers or particles).3 Composite materials are very much ideal for numerous engineering applications for their desired strength-to-weight ratio or stiffness-to-weight ratio. The matrix and reinforcement traditionally used are synthetic in nature. Epoxy resin is generally used as a most common matrix for the fabrication of composite material.4-6 Apart from the usage of synthetic resins, synthetic fibers are also used as a reinforcement material for the development of composite materials. However, following the practice of using synthetic fibers as reinforcement with synthetic matrix, the fabrication of composite materials is found to be less effective in terms of cost and eco-friendliness. To overcome these challenges for developing cost-effective composite materials, hybrid composites have been taken into consideration for obtaining significant mechanical properties. The application of natural fiber-reinforced composites is growing rapidly due to their inherent properties of lightweight, easy availability, and environment friendliness.7 The combination of natural fiber with synthetic fiber provides enhanced mechanical properties, hence it is found to be a good alternative for reinforcement material. The mechanical properties of the carbon-jute-glass fibers reinforced epoxy laminate composites can be enhanced by using a combination of these reinforcement materials along with different stacking sequences.8,9 Sujon et al. collectively worked on the placement of different layers of jute and carbon fiber in different positions inside the composite and investigated experimentally the change in tensile strength and flexural strength of the material along with the change in stacking sequence.10 Velmurugan et al. suggested that with the addition of glass fiber in a glass fiber-based hybrid composite, there is a significant enhancement in the mechanical properties of the composite material.11 Manikantesh et al. studies have implied that the fiber stacking sequence and orientation play an important role in the tensile properties of the composite. In the case of jute/glass/hemp epoxy-based composite, the maximum tensile strength is obtained for the horizontal orientation of the jute fiber.12 EI-baky et al. have investigated the physical examination of the mechanical behavior of hybrid reinforced composites of jute, glass, and carbon fiber and pointed out that the void content of composites decreases when jute-reinforced composites are hybridized with glass and/or carbon fiber.13 Pothan et al. have studied banana-glass hybrid composites and found the overlay model or geometry of the composite has a deep impact on the dynamic behavior of composites.14 Onal et al. have studied the impact of stacking sequences on the mechanical properties of Glass-Carbon hybrid epoxy composites pre and post-impact.15 Jawaid et al. examined the mechanical behavior of the hybrid jute-based composites with oil palm fiber. It has been pointed out that the utilization of a hybrid system was effective in enhancing the mechanical properties of oil palm hybrid epoxy composite due to improved bonding of the fiber-matrix interface.16

The works of literature that are available point out that jute fiber-reinforced composites are chiefly hybridized with glass fibers.17 However, in the current research work, the jute fiber is hybridized with carbon and glass fiber in the epoxy-resin matrix. In this context, the major objective of this research is to fabricate and study the new hybrid composite laminate by the hybridization of jute, glass, and carbon fiber with help of epoxy-resin at different stacking and orientation of fiber without varying the fiber content. The effect of stacking sequences and orientation of fibers on the tensile and flexural properties have been investigated. The obtained mechanical properties for the newly manufactured hybrid composite with environmentally friendly attributes are best suited for a wide range of engineering applications that are more economically and functionally structured.

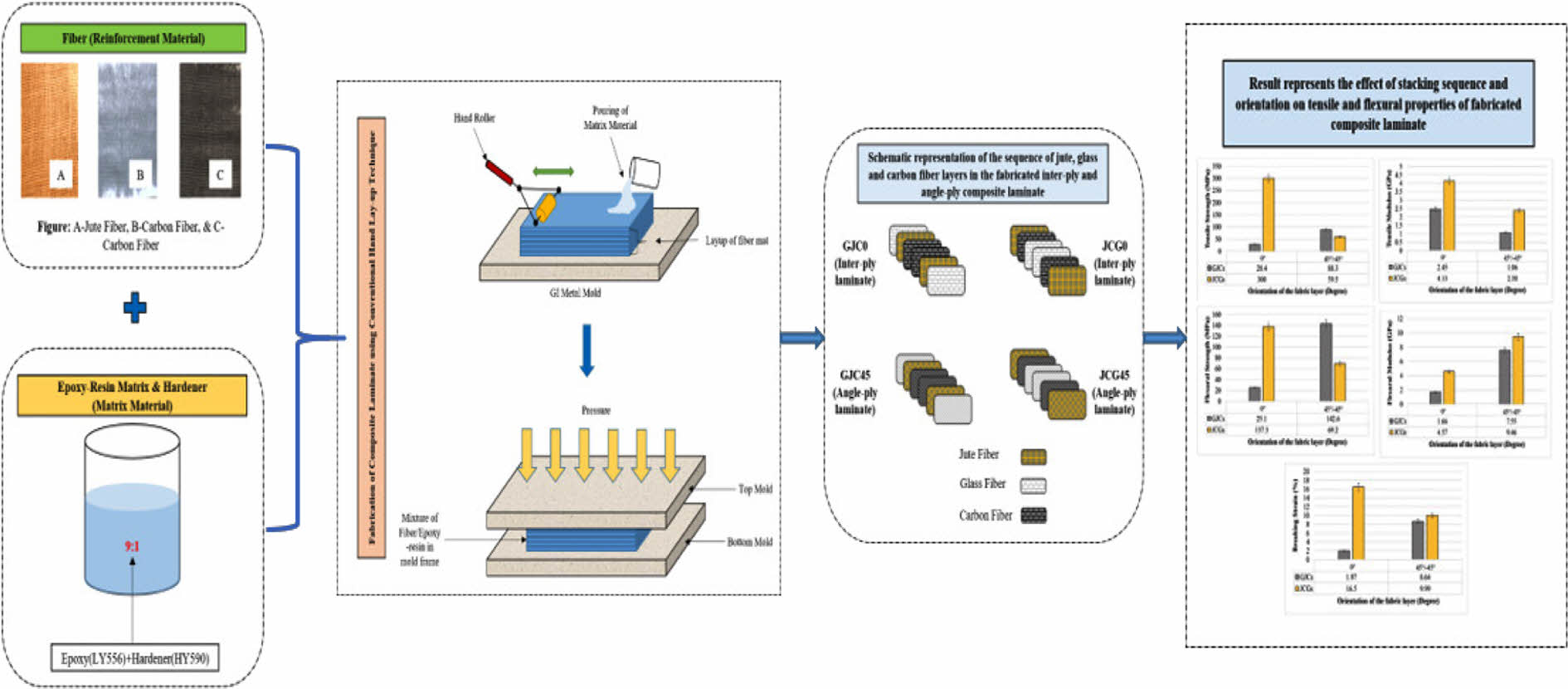

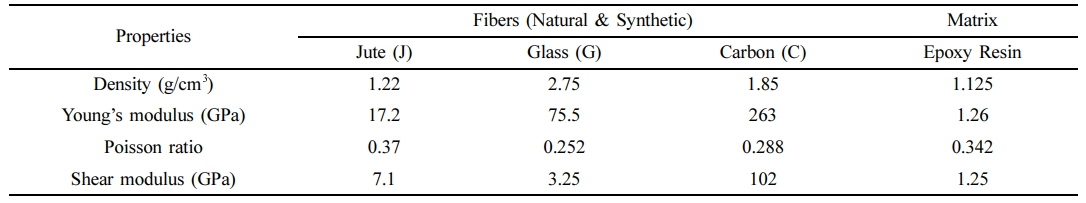

Materials and Methods. Typically, composite laminates are fabricated using the conventional hand lay-up technique. For the fabrication of hybrid composite laminates, jute fiber (bidirectional), carbon fiber (unidirectional), and glass fiber (unidirectional) have been used as the reinforcement, and epoxy resin as a matrix material. The glass fiber, carbon fiber, and jute fiber have been provided by Vihan Techno Trade, Gujrat, India. Epoxy resin matrix and corresponding hardener are supplied by Herenba Instruments & Engineers, Chennai, India. The surface texture of the fibers is shown in Figure 1. For the fabrication of the composites, epoxy resin is mixed with a hardener in a 9:1 ratio and cured at room temperature. The properties of the epoxy and fibers are listed in Table 1.

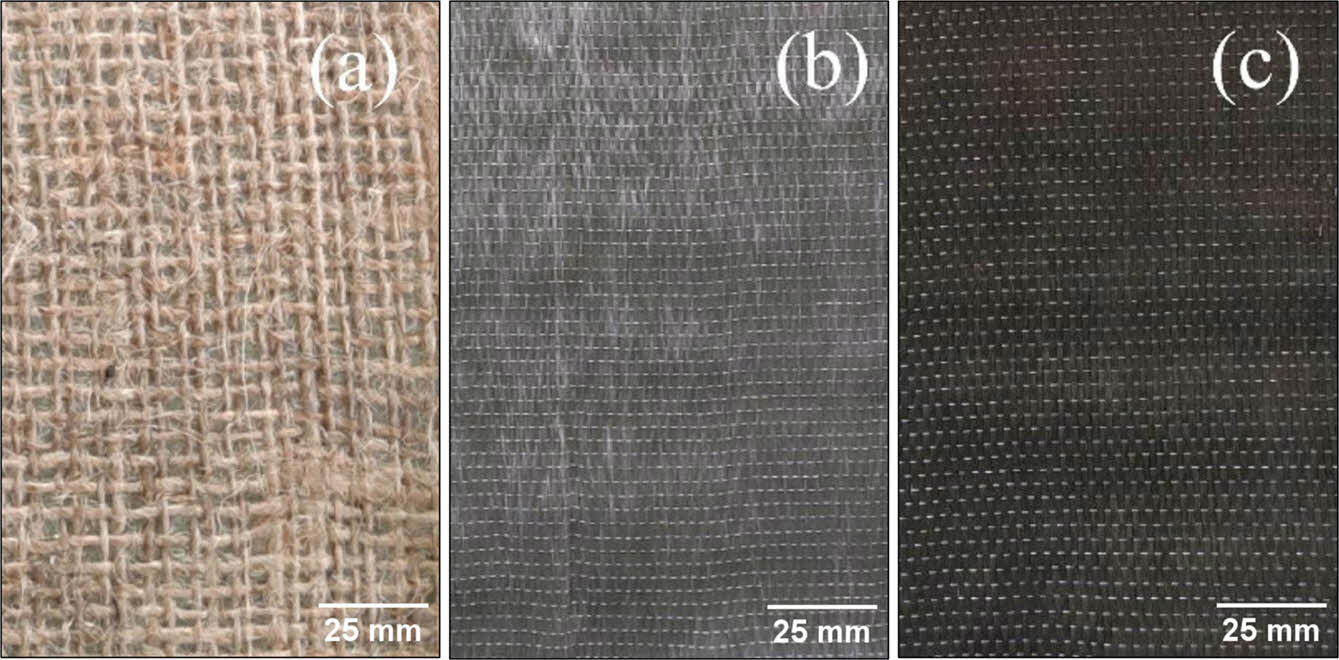

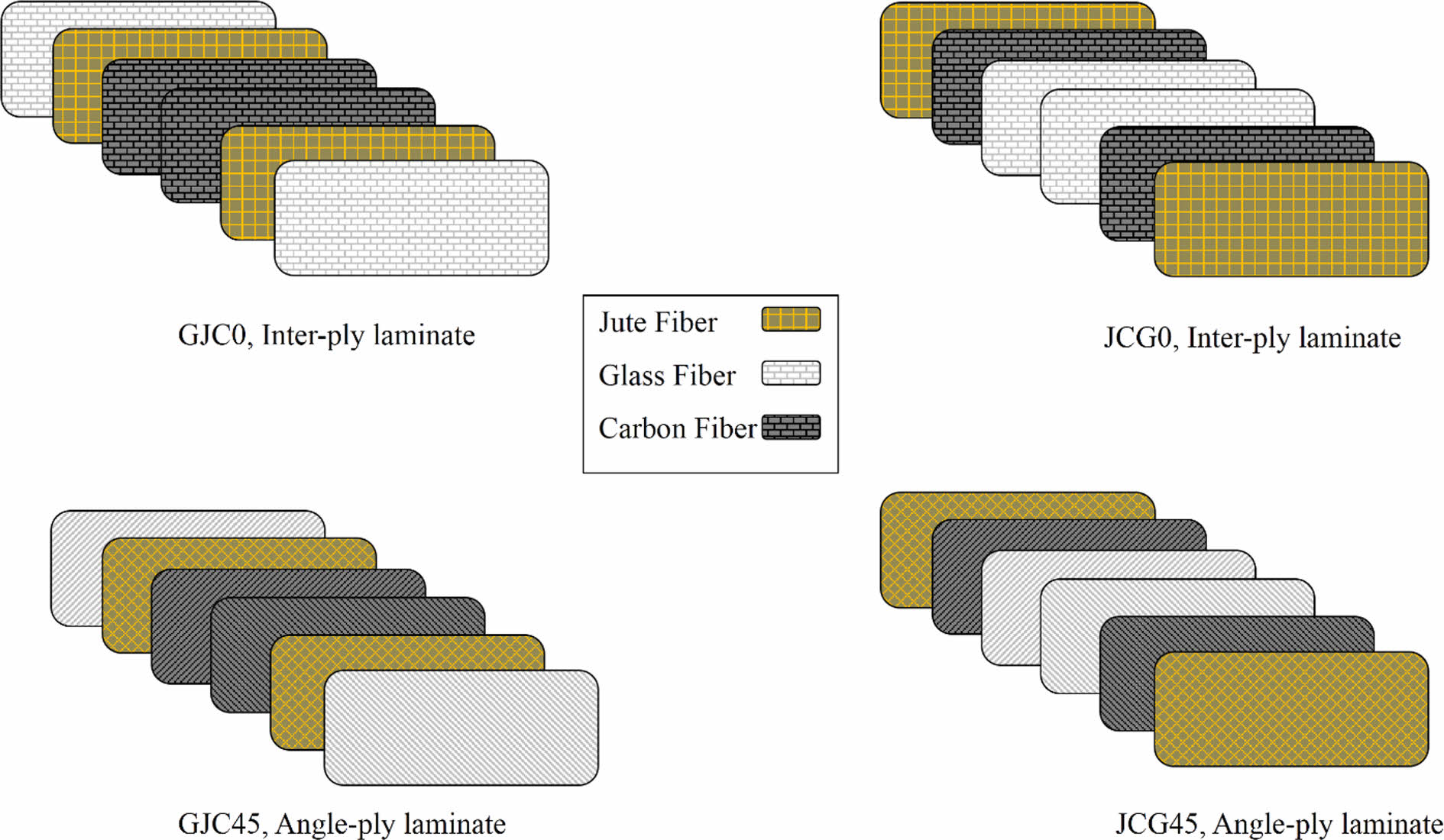

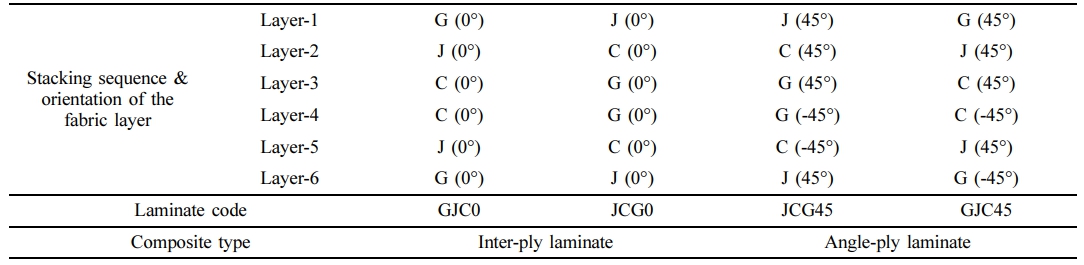

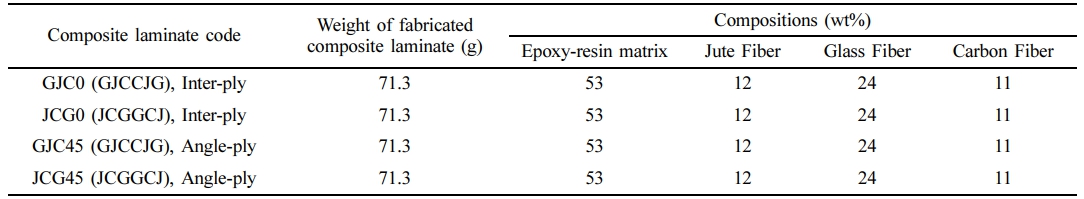

Sample Preparation. In a typical experimental procedure, for the fabrication of composite samples S1, S2, S3, and S4, firstly the fibers were prepared and cut into the desired dimensions & orientation i.e. 0° and 45°/-45°. The fabrication of the hybrid composite laminate structures is performed using the conventional hand lay-up technique.19 Initially, the fibers are manually placed in a layer-by-layer form on the galvanized iron (GI) metal plate which was primarily coated with a mold release wax.20 The brush is used to apply the mixture of epoxy resin and hardener on the reinforcing material. The grade used for the epoxy-resin matrix and hardener is LY556 and HY590, respectively.21,22 Furthermore, a hand roller has been used for the even distribution of the mixture of epoxy resin and hardener on the reinforcements to improve the interaction among the fibers and the matrix and to achieve the required thickness of the hybrid composite laminates.23 After this, the curing process was carried out in an open atmosphere for 48 h at room temperature.24 After the curing process, the fabricated hybrid composite laminates were removed from the metal plate. In one case, laminate composites of 150×100×3 mm with glass fibers at the top and bottom layers and jute and carbon fibers in the intermediate layers have been fabricated for the inter-ply (fibers are stacked at 0°) and angle-ply (fibers are stacked at an angle) laminates. In another case, laminate composites with jute fibers at the top and bottom layers and carbon and glass fibers in the intermediate layers have been fabricated for the inter-ply and angle-ply laminates. The fabricated laminate composites with their designation, desired orientation, and composition (wt%) of fibers are illustrated in Tables 2 and 3. Also, the layering arrangement of fabricated hybrid composite laminates has been represented in Figure 2. The room temperature cured laminate composite samples have been shown in Figure 3.

|

Figure 1 Surface texture photographs of (a) jute fiber (bidirectional); (b) glass fiber (symmetric); (c) carbon fiber (symmetric). |

|

Figure 2 Schematic representation of the sequence of jute, glass and carbon fiber layers in the fabricated inter-ply and angle-ply composite laminates. |

|

Figure 3 (a) GJC0 (Inter-ply); (b) JCG0 (Inter-ply); (c) JCG45 (Angle-ply); (d) GJC45 (Angle-ply) laminate composites. |

The purpose of the mechanical testing of composite materials is to identify the various mechanical properties such as tensile strength, flexural strength, and breaking strain. In this research, the investigation has been done on the tensile properties and flexural properties of samples of GJCs and JCGs laminated composites at 0° & 45°/-45° fibers orientation.

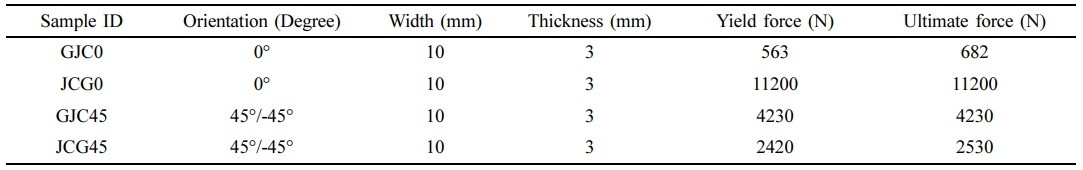

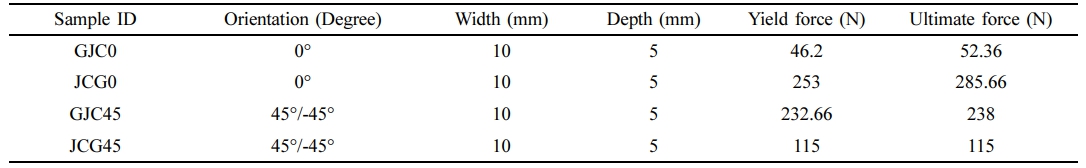

Tensile Test. The ASTM D638 is the standard test procedure to identify the tensile properties of rectangular composite laminate.25 A strain gauge is used to determine the strain extension and tensile modulus of the specimen. The loading arrangement of the test sample for the tensile test is shown in Figure 4. The following Table 4 has shown the loading condition of composite laminate for the tensile test.

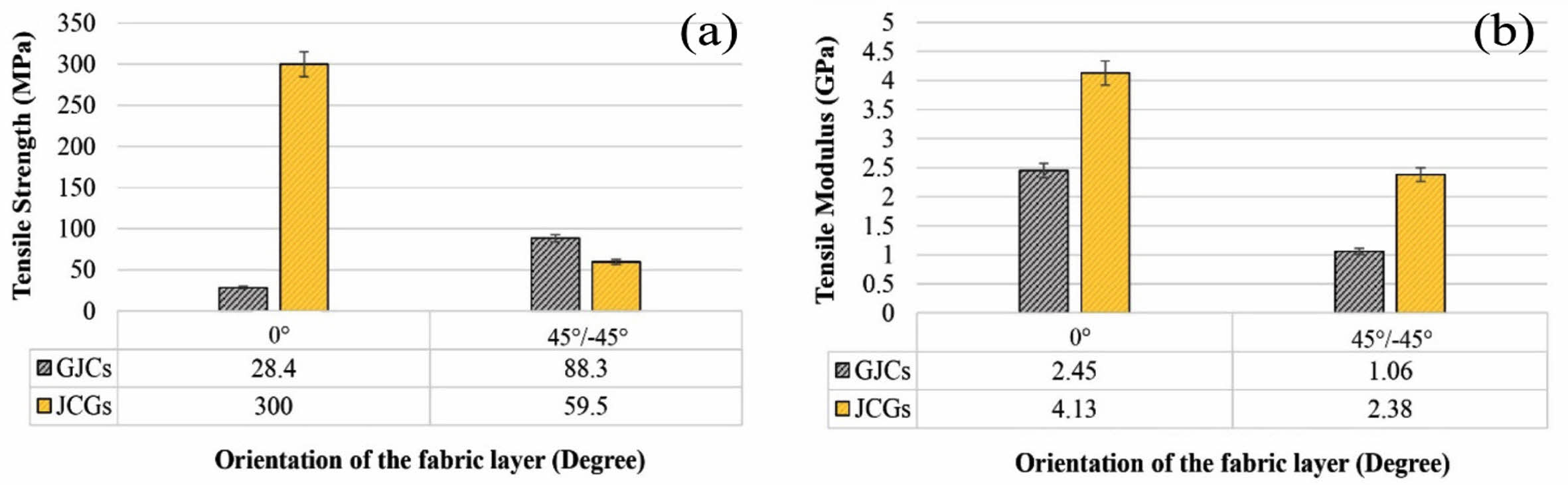

The tensile test was conducted for rectangular specimens of the composite laminates of size 150×10×3 mm. The variation of tensile properties of composites is shown in Figure 5(a) and (b). It has been observed from Figure 5(a) that the tensile strength of the GJCs composite is lower than the JCGs composite at 0° orientations and higher than at 45°/-45° orientations. Usually, this variation is caused due to poor adhesion between the fibers and the epoxy-resin matrix.26 It has also been observed that with an increase in the orientation of fibers from 0° to 45°/-45°, the tensile strength increases for GJCs composite and decreases for JCGs composite. JCG0 sample exhibited higher tensile strength compared to JCG45 because all the fibers are oriented in the direction of the applied load in case of JCG0 imparting higher resistance against the deformation. However, at 45°/-45° fiber orientation, there is not effective transfer of stress from the matrix in case of JCG45. From Figure 5(b), it has been noticed that the tensile modulus of the JCGs composite is much greater than the GJCs composite at 0° as well as at 45°/-45° orientation of fibers. It can be easily seen that with the increase in the orientation of fibers from 0° to 45°/-45°, the tensile modulus decreases for GJCs composite as well as for JCGs composite. Generally, the variation of the values of tensile modulus of both the composite is due to the improper adhesion of the fibers and the epoxy-resin matrix.26 It can be observed from the result that, the tensile strength and tensile modulus of the JCGs composite are greater than the GJCs composite by 90.53% and 40.67%, respectively, at 0° orientation of fibers. The strength of the glass and carbon fibers are much higher compared to jute fibers. Therefore, due to the presence of high strength carbon and glass fibers in the core, the JCG0 composite laminates exhibits good tensile strength compared to GJC0 where weaker jute fibers are placed in the core. The tensile modulus of the JCGs composite laminate is higher than the GJCs composite laminate by 55.46%, but the tensile strength of JCGs composite laminate is lower than the GJCs composite by 32.61% at 45°/-45° orientation of fibers.

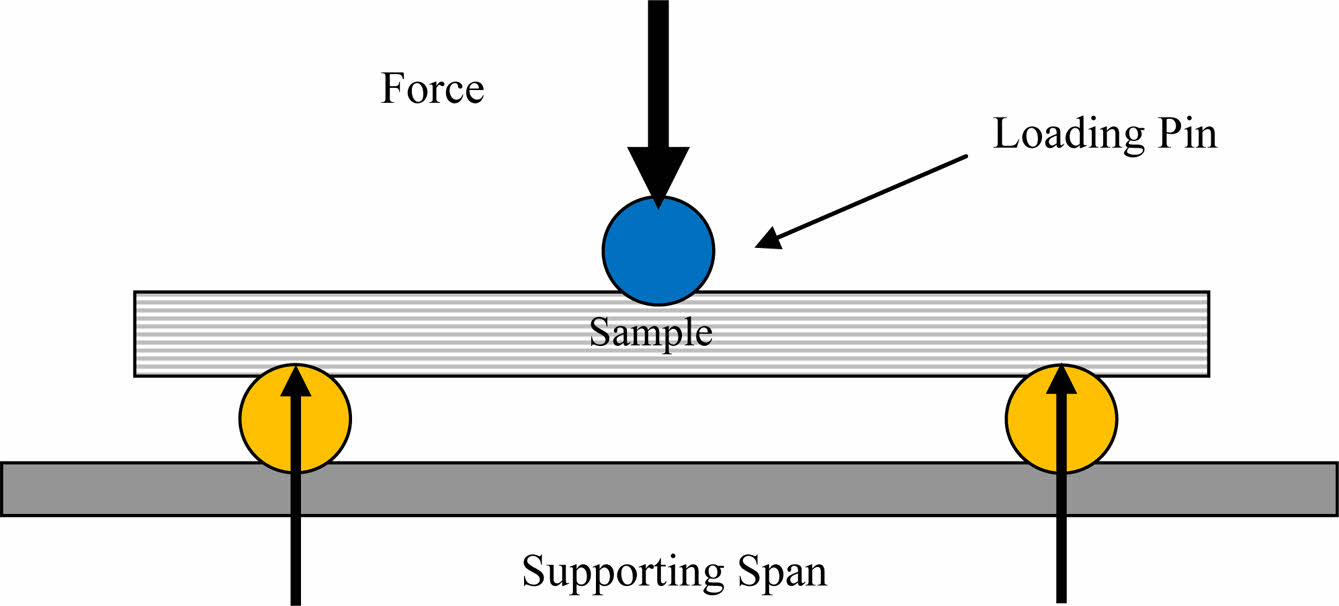

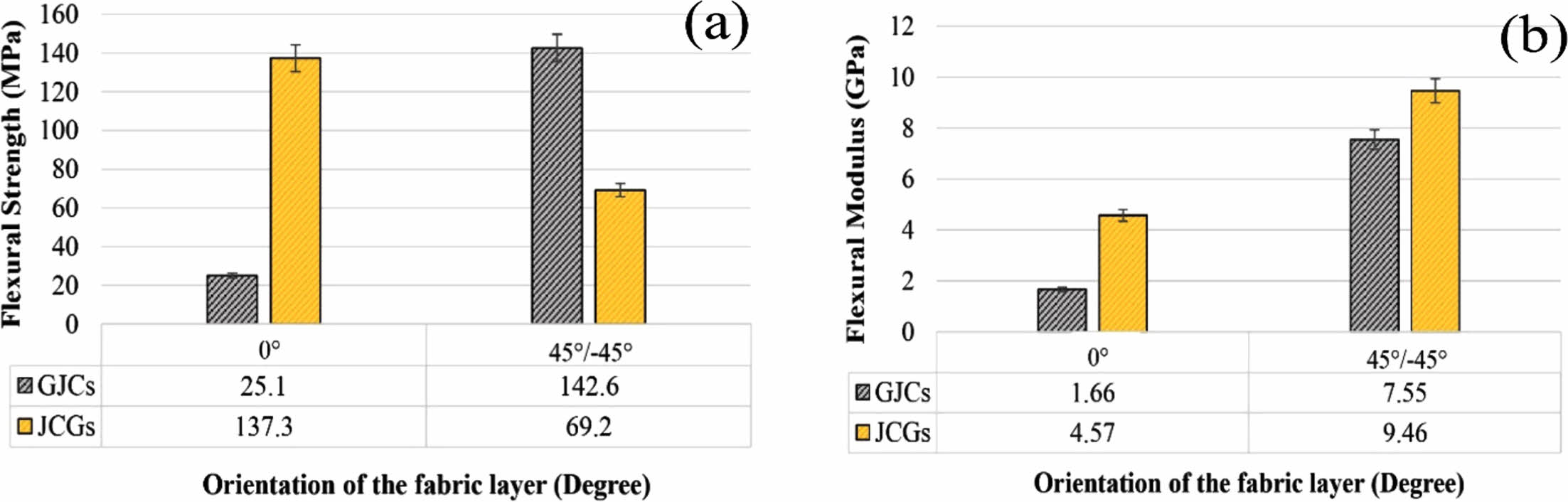

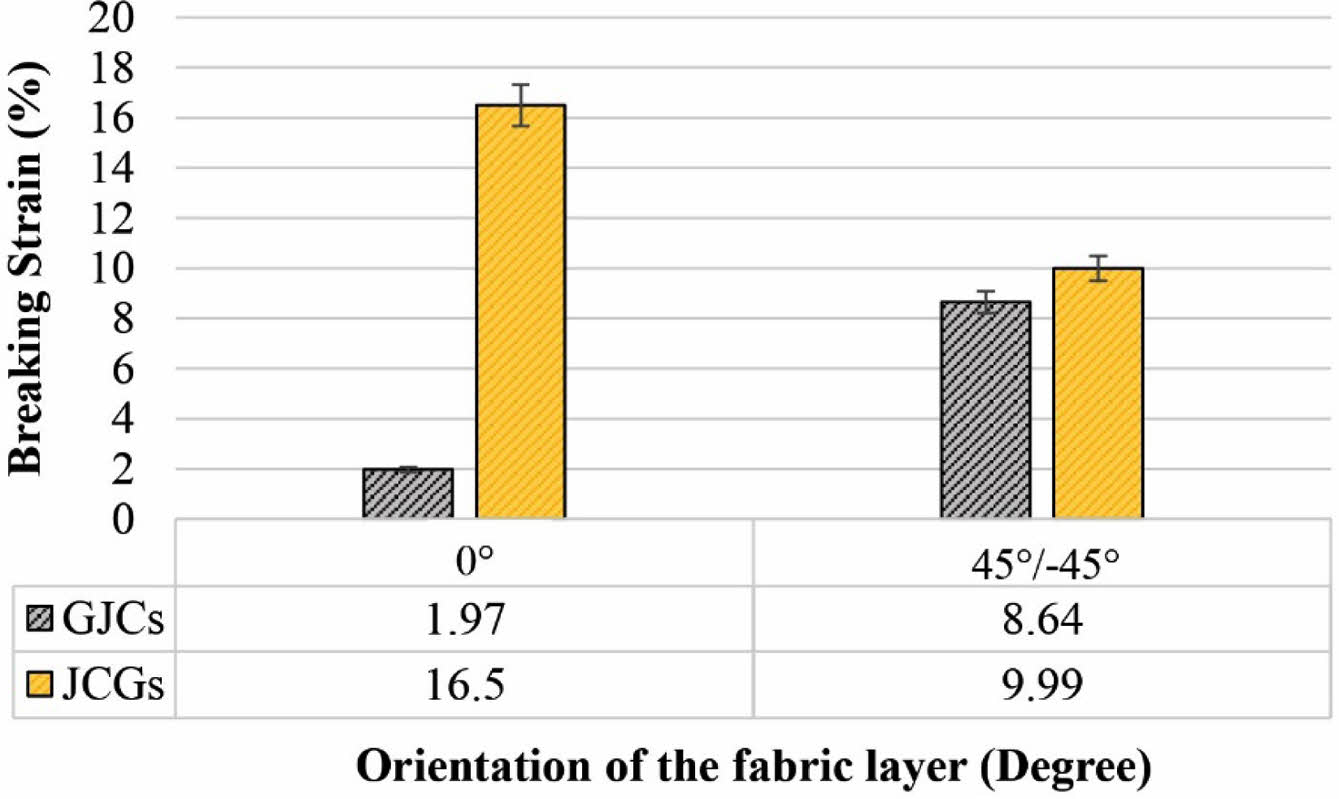

Flexural Test. The purpose of the flexural test is to determine the ability of a material to resist bending before reaching the point of failure. Usually, the test sample is placed onto the supported staff and the load is applied at the center of the test sample with the help of the loading nose, which produces three-point bending at s desired feed rate.27 The specimens were cut (120×10×3 mm) and flexural test was carried out (supported span length 51 mm) according to ASTM D790 standard.27 Figure 6 shows the free-body diagram and Figure 7 shows the experimental setup and loading arrangement of the specimen for the flexural test. The average depth for the flexural test has been taken as 5 mm. The loading condition for the flexural test has been illustrated in Table 5. The effect of loading, stacking sequence, and orientation of fibers on the flexural strength and flexural modulus of the composites are illustrated in Figure 8(a) and (b). It is evident from Figure 8(a), at the 0° orientation of fibers, the flexural strength of GJCs composite is lower than the JCGs composite and at the 45°/-45° orientation of fibers, the flexural strength of GJCs composite is higher than the JCGs composite. It is also seen that with the increase in the orientation of fibers from 0° to 45°/-45°, the flexural strength increases for GJCs composite and decreases for JCGs composite. It is noted that both the stacking sequence and orientation of fibers have a substantial impact on the flexural strength of the composite materials. From Figure 8(b), it has been observed that the flexural modulus of the JGCs composite is much higher than the GJCs composite at 0° and 45°/-45° orientation of fibers. It is also observed that with the increase in the orientation of fibers from 0° to 45°/-45°, the flexural modulus increases GJCs as well as JCGs composite. From Figure 9, it is seen that the breaking strain of GJCs composite is much higher than the JCGs composite by 88.06% at 0° and 13.6% at 45°/-45° orientation of the fibers respectively. As a result, the ductility of JCGs composite is much higher at 0° as compared to 45°/-45° orientation of the fibers, but for GJCs composite, the ductile is much lesser at 0° as compared to 45°/-45° orientation of the fibers. It can be seen from the results that, the flexural strength and flexural modulus of the JCGs composite are higher than the GJCs composite by 81.71% and 63.70% respectively at 0° orientation of fibers. The flexural modulus of the JCGs composite laminate is higher than the GJCs composite laminate by 20% but the flexural strength of JCGs composite laminate is lower than the GJCs composite by 51.47% at 45°/-45° orientation of fibers.

|

Figure 4 The loading arrangement of the test sample in the tensile test machine. |

|

Figure 5 Variation of the (a) tensile strength; (b) tensile modulus of the composite laminates with the fiber orientation |

|

Figure 6 Free body diagram of test sample for flexural test. |

|

Figure 7 The experimental setup and loading arrangement of specimens for the flexural test. |

|

Figure 8 Variation of the (a) flexural strength; (b) flexural modulus of the composite laminates with the fiber orientation. |

|

Figure 9 Variation of breaking strain of the composite with the orientation of fibers. |

The impact of effective stacking sequence and orientation of jute(J)/glass(G)/carbon(C) fiber epoxy-based hybrid composite laminates in terms of tensile and flexural properties were investigated. The JCGs hybrid composite laminate fabricated with 0° orientations at the inner glass fabric layer exhibited increased tensile and flexural properties than the GJCs hybrid composite laminate at the same orientation. The hybrid arrangement of GJCs composite laminate fabricated with 45°/-45° orientation at the inner carbon fabric layer exhibited increased tensile and flexural strength as compared JCGs hybrid composite laminate at the same orientation. JCGs offered a significant increase in tensile and flexural modulus nearly about 55% and 20%, respectively at 45°/-45° orientation as compared to the other arrangement. The JCGs composite is more ductile than the GJCs composite. Also, the stiffness of the JCGs composite is much greater than that of the GJCs composite at both orientations of fiber layers. The JCGs composite exhibits excellent mechanical properties such as tensile strength (at 0° orientation of fabric layer), tensile modulus, flexural strength (at 0° orientation of fabric layer), flexural modulus, stiffness, and ductility at different orientations and stacking sequences without varying the epoxy-resin matrix compositions. This enhanced mechanical performance of JCGs (at 0° and 45°/-45° orientation of fabric layer) hybrid laminate was owing to the glass fiber’s inherent ability to maintain some characteristics such as bonding between the carbon fiber and jute fiber. As the jute fibers have weak interaction with the carbon fibers, the placement of jute fibers in the core of the laminate composites severely affects the performance of the carbon fibers. The placement of jute fibers in the core of the composite laminates generally leads to problem of delamination and debonding inside the laminates resulting in deterioration of the mechanical properties. The improved tensile and flexural properties of the JCGs composite laminate, which has an inner layer of glass fabric and an adjacent layer of high modulus carbon fabric at 0°orientation portray potential for industrial applications.

- 1. Karimah, A.; Ridho, M. R.; Munawar, S. S.; Adi, D. S.; Ismadi, Damayanti, R.; Subiyanto, B.; Fatriasari, W.; Fudholi, A. A Review on Natural Fibers for Development of Eco-friendly Bio-Composite: Characteristics, and Utilizations. J. Mater. Res. Technol. 2021, 13, 2442-2458.

-

- 2. Ngo, T. Introduction to Composite Materials. In Composite and Nanocomposite Materials, 1st ed.; Ngo, T., Eds.; Intech Open: United Kingdom, 2020, DOI: 10.5772/intechopen.91285.

- 3. Sharma, A. K.; Bhandari, R.; Aherwar, A.; Rimašauskiene, R. Matrix Materials Used in Composites: A Comprehensive Study. Mater. Today: Proc. 2020, 21, 1559-1562.

-

- 4. Zhao, X.; Lu, S.; Li, W.; Zhang, S.; Li, K.; Nawaz, K.; Wang, P.; Yang, G.; Ragauskas, A.; Ozcan, S.; Webb, E. Epoxy as Filler or Matrix for Polymer Composites. In Epoxy-Based Composites, 1st ed.; Chelladurai, S. J. S., Arthanari, R., Meera, M. R., Eds.; IntechOpen: United Kingdom, 2022, DOI: 10.5772/intechopen.97898.

-

- 5. Abdellaoui, H.; Raji, M.; Bouhfid, R.; Qaiss, A. 2-investigation of the Deformation Behavior of Epoxy-Based Composite Materials. In Failure Analysis in Biocomposites, Fiber-Reinforced Composites and Hybrid Composites, 1st ed.; Jawaid, M., Thariq, M., Saba, N., Eds.; Woodhead Publishing, Elsevier: Duxford, 2019, pp. 29-49.

-

- 6. Ramakrishnan, T.; Gift, M. D. M.; Chitradevi, S.; Jegan, R.; Jose, P. S. H.; Nagaraja, H. N.; Sharma, R.; Hailegiorgis, S. M. Study of Numerous Resins Used in Polymer Matrix Composite Materials. Adv. Mater. Sci. Eng. 2022, 2022, 1088926.

-

- 7. Rajak, D. K.; Wagh, P. H.; Linul, E. A. Review on Synthetic Fibers for Polymer Matrix Composites: Performance, Failure Modes, and Applications. Materials 2022, 15, 4790.

-

- 8. Velu, S.; Joseph, J. K.; Sivakumar, M.; Raja, V. K. B.; Palanikumar, K.; Lenin, N. Experimental Investigation on the Mechanical Properties of Carbon-Glass-Jute Fiber Reinforced Epoxy Hybrid Composites. Mater. Today: Proc. 2021, 46, 3566-3571.

-

- 9. Venkatasudhahar, M.; Kishorekumar, P.; Raja, N. D. Influence of Stacking Sequence and Fiber Treatment on Mechanical Properties of Carbon-Jute-Banana Reinforced Epoxy Hybrid Composites. Int. J. Polym. Anal. Charact. 2020, 25, 238-251.

-

- 10. Sujon, A. S.; Supto, T. H.; Shariar, F.; Pallab, M. M. R.; Abedin, M. Z.; Habib, M. A. Fabrication and Experimental Investigation on Tensile and Flexural Properties for Different Stacking Sequence of Jute and Carbon Fiber Reinforced Epoxy Composite. Key Eng. Mater. 2020, 858,72-77.

-

- 11. Velmurugan, R.; Manikandan, V. Mechanical Properties of Palmyra/Glass Fiber Hybrid Composites. Compos. A: Appl. Sci. Manuf. 2007, 38, 2216-2226.

-

- 12. Naresh, Ch.; Kumar, Y. R.; Manikantesh, K. Effect of Stacking Sequence and Orientation on Tensile Response of Natural Fiber Reinforced Hybrid Composites: Fibrous-Glass/Hemp/Jute/ Epoxy Composite Plates. Int. J. Eng. Res. Technol. 2016, 5, 161-167.

-

- 13. Abd El-baky, M. A. Evaluation of Mechanical Properties of Jute/Glass/Carbon Fibers Reinforced Hybrid Composites. Fibers Polym. 2017, 18, 2417-2432.

-

- 14. Pothan, L. A.; George, C. N.; John, M. J.; Thomas, S. Dynamic Mechanical and Dielectric Behavior of Banana-Glass Hybrid Fiber Reinforced Polyester Composites. J. Reinf. Plast. Compos. 2010, 29, 1131-1145.

-

- 15. Onal, L.; Adanur, S. Effect of Stacking Sequence on the Mechanical Properties of Glass-Carbon Hybrid Composites Before and After Impact. J. Ind. Text. 2002, 31, 255-271.

-

- 16. Jawaid, M.; Khalil, H. P. S. A.; Hassan, A., Dungani, R.; Hadiyane, A. Effect of Jute Fiber Loading on Tensile and Dynamic Mechanical Properties of Oil Palm Epoxy Composites. Compos. B: Eng. 2013, 45, 619-624.

-

- 17. Nagaraja, K. C.; Rajanna, S.; Prakash, G. S.; Koppad, P. G.; Alipour, M. Studying the Effect of Different Carbon and Glass Fabric Stacking Sequence on Mechanical Properties of Epoxy Hybrid Composite Laminates. Compos. Commun. 2020, 21, 100425.

-

- 18. Parbin, S.; Waghmare, N. K.; Singh, S. K.; Khan, S. Mechanical Properties of Natural Fiber Reinforced Epoxy Composites: A Review. Procedia Comput. Sci. 2019, 152, 375-379.

-

- 19. Kim, S. Y.; Shim, C. S.; Sturtevant, C.; Kim, D. W.; Song, H. C. Mechanical Properties and Production Quality of Hand-Layup and Vacuum Infusion Processed Hybrid Composite Materials for GFRP Marine Structures. Int. J. Nav. Archit. Ocean Eng. 2014, 6, 723-736.

-

- 20. Neves, A. C. C.; Rohen, L. A.; Mantovani, D. P.; Carvalho, J. P. R. G.; Vieira, C. M. F.; Lopes, F. P. D.; Simonassi, N. T.; da Luz, F. S.; Monteiro, S. N. Comparative Mechanical Properties Between Biocomposites of Epoxy and Polyester Matrices Reinforced by Hemp Fiber. J. Mater. Res. Technol., 2020, 9, 1296-1304.

-

- 21. Alam, M. S.; Chowdhury, M. A. Characterization of Epoxy Composites Reinforced with CaCO3-Al2O3-MgO-TiO2/CuO Filler Materials. Alex. Eng. J. 2020, 59, 4121-4137.

-

- 22. Srikar, B.; Rao, L. V. V.G. A Study on Mechanical Properties of Hybrid Fiber Reinforced Polymer Composites. IOP Conf. Ser.: Mater. Sci. Eng. 2021,1185, 012037.

-

- 23. Atmakuri, A.; Palevicius, A.; Kolli, L.;Vilkauskas, A.; Janusas, G. Development and Analysis of Mechanical Properties of Caryota and Sisal Natural Fibers Reinforced Epoxy Hybrid Composites. Polymers 2021, 13, 864.

-

- 24. De Castro, F. L. A.; Campos, B. B.; Bruno, K. F.; Reges, R. V. Temperature and Curing Time Affect Composite Sorption and Solubility. J. Appl. Oral Sci. 2013, 21, 157-162.

-

- 25. ASTM D638, Standard Test Method for Tensile Properties of Plastics. ASTM International, West Conshohocken, PA, USA 2014.

- 26. Plonka, R.; Mäder, E.; Gao, S. L.; Bellmann, C.; Dutschk, V.; Zhandarov, S. Adhesion of Epoxy/Glass Fiber Composites Influenced by Aging Effects on Sizings. Compos. Part A Appl. Sci. Manuf. 2004, 35, 1207-1216.

-

- 27. Gupta, U. S.; Dhamarikar, M.; Dharkar, A.; Tiwari, S.; Namdeo, R. Study on the Effects of Fiber Volume Percentage on Banana-Reinforced Epoxy Composite by Finite Element Method. Adv. Compos. Hybrid Mater. 2020, 3, 530-540.

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2022 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2023; 47(5): 574-581

Published online Sep 25, 2023

- 10.7317/pk.2023.47.5.574

- Received on Jan 28, 2023

- Revised on Apr 26, 2023

- Accepted on Jun 13, 2023

Services

Services

- Full Text PDF

- Abstract

- ToC

- Conflict of Interest

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Samarjit Singh, Rakesh Bhaskar*

-

Department of Mechanical Engineering, School of Studies of Engineering & Technology, Guru Ghasidas Vishwavidyalaya, Bilaspur, Chhattisgarh-495009, India

*School of Chemical Engineering, Yeungnam University, Gyeongsan-38541, Korea - E-mail: samarjitsingh05@gmail.com, indiaxenobiotic@gmail.com

- ORCID:

0000-0002-2764-7037, 0000-0002-0181-6197

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.